Want to keep your chemical plant pipes super safe? Discover how grooved couplings stop leaks, cut downtime, and handle tough high-pressure jobs!

What Are Grooved Couplings and Why Are They Cool for Pipes?

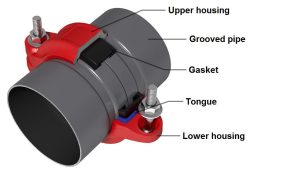

Grooved couplings are super important parts in pipe systems. They join pipes tight and fast. These fittings use a special grooved-end design. Pipes snap together with a coupling cover and bolts. This skips hard stuff like welding, making them awesome for many jobs.

What Makes Grooved Couplings Special

Grooved couplings are like cool connectors. They link pipe ends with grooves cut on the outside. The coupling housing wraps around these grooves. It makes a strong fit. Here’s what makes them neat:

- Easy Setup: You need just a few tools and little work to put them up.

- No Leaks: Their tight grip keeps liquids from sneaking out.

- Bend a Bit: Some let pipes move a little for heat changes.

- Super Tough: Made with strong stuff like ASTM A536 and ASTM A395, they last a long time.

Where Chemical Plants Use Grooved Couplings

Chemical plants love grooved couplings because they’re trusty and work in many spots. They’re used in:

- Chemical Lines: Keeping dangerous stuff locked in tight.

- Cooling Systems: Helping HVAC keep things chill.

- Fire Safety: Making sprinkler pipes strong for emergencies.

- High-Pressure Pipes: Handling big pressure, like with the XGOT02 flexible grooved coupling, built for tough spots up to 363 psi.

Why They’re a Big Deal

Grooved couplings are like a superhero for pipes. They make setups easy and keep things safe. They’re perfect for chemical plants’ tricky jobs.

Why Are Grooved Couplings Super Important for Safety?

Safety is a huge deal in chemical plants. They handle dangerous stuff every day. Grooved couplings help keep everyone and everything safe.

Stopping Leaks with Grooved Pipe Fittings

Leaks in chemical pipes can cause big trouble, like hurting the environment or people. Grooved pipe fittings, like the XGQT18 mechanical cross, make super tight connections. They’re built tough. Their smart design leaves no gaps. This stops leaks even with high pressure or super hot or cold temps.

Cutting Down on Pipe Breaks and Mishaps

Old-school methods like welding can get weak over time. Rust or stress can break them. But grooved couplings spread stress evenly. This makes pipe breaks less likely. Fewer breaks mean fewer accidents or big shutdowns. Your plant stays safer.

Handling Tough High-Pressure Jobs

Chemical plants often have pipes with crazy high pressure. Fittings like the XGQT13 adapter flange can take up to 363 psi. They stay strong and keep things safe, even in wild conditions.

Why Safety Rocks with Grooved Couplings

They’re like a safety shield for your pipes. They stop leaks and keep pipes strong. This makes them a must-have for chemical plants.

How Do Grooved Couplings Make Fixing and Upkeep Easy?

Keeping things running smooth in chemical plants is super important. Grooved couplings make fixes and checks quick and simple.

Fast Setup and Swap-Outs

Grooved couplings are super easy to set up compared to welding. Parts like the XGQT15S mechanical tee threaded are made for quick setup. Workers can swap out broken bits fast. They don’t need fancy tools. This saves tons of time.

Less Waiting Time During Fixes

Time matters a lot in chemical plants. Grooved couplings let you take apart and fix pipes fast. You don’t need to cut pipes or use big machines. This cuts downtime. Your plant keeps running without big breaks. Vicast’s products, like the XGQT02 rigid grooved coupling, are tough and made for quick fixes. They stay strong even after lots of setups.

More Fixing Tricks

Keep a spare coupling like the XGQT13 adapter flange ready. Check your system every few months for loose spots. These keep your pipes running great.

What Makes Vicast a Trusty Supplier for Grooved Fittings?

Vicast is a big name for getting awesome grooved fittings. They’re known for making super good stuff that lasts.

About Vicast’s Quality and Cool Products

Vicast makes top-notch grooved pipe fittings with strong materials like ASTM A536, Grade 65-45-12, and ASTM A395, Grade 65-45-15. These don’t wear out easy. Their products meet big rules like ISO6182, AWWA C606, and GB 5135.11. This means they work great every time.

They have lots of products for different jobs. The XGQT02 rigid grooved coupling is perfect for high-pressure spots. It keeps pipes tight with no leaks. Their mechanical tees and crosses, like the XGQT18 mechanical cross, are great for HVAC, fire systems, and big industrial pipes. They make things safer and stronger.

Why Pick Vicast for Chemical Plants

Vicast has been a top pick in China for over 40 years. They’ve worked on huge projects like the 2008 Beijing Olympics and the Canton Tower. Their fittings are used in big places like the Guangzhou International Convention Center. This shows they’re pros at big jobs.

Chemical plants need pipes that handle high pressure, hot or cold temps, and dangerous stuff. Vicast’s products, like the XGQT13 adapter flange, take up to 363 psi. They’re trusty in tough spots. Their grooved couplings make setup and fixes easy while keeping pipes tight.

Plus, Vicast cares about the planet. They use green ways to make their products. This helps the environment while giving you awesome fittings.

Why Vicast Is Super Cool

Vicast’s focus on quality makes them stand out. Their fittings are tough and work great. They help customers from start to finish. This makes them a go-to for chemical plant pros.

Why Grooved Couplings Are Awesome for Safety

Grooved couplings make chemical plant pipes safer and better. They stop leaks, cut fixing time, and handle tough jobs. Vicast’s products, like the XGQT15S mechanical tee threaded, are built to last. With a little care, your pipes stay strong and keep everyone safe.

Conclusion: Why Picking the Right Pipe Fittings Matters

Choosing the best pipe fittings is a big deal for chemical plant safety. Grooved couplings beat old methods by stopping leaks, saving time, and staying strong in tough spots. Vicast offers trusty products like the XGQT18 mechanical cross and the XGQT13 adapter flange that meet big standards. They’re a great pick for keeping your plant safe and running smooth.

FAQs About Grooved Couplings in Chemical Plant Piping Systems

Q1: How Are Grooved Couplings Different from Old Pipe Joins?

They use a snap-together system, not welding or threading. This makes them easier to set up and fix. They don’t need fancy tools or lots of work.

Q2: Can Grooved Couplings Handle Hot Jobs?

Yup! Most work great from -20°F to +180°F (-29°C to +82°C). They’re perfect for tough plant jobs.

Q3: Can You Use Grooved Couplings Again After Taking Them Apart?

Totally! They’re reusable. You can take them off and put them back without breaking them.