Picking the proper pipe fittings for your job is a vital choice. This choice greatly affects how well your plumbing or factory systems work. It impacts safety and how long they last. You might be dealing with heating and cooling gear, fire safety setups, water delivery lines, or factory uses. Finding the correct fittings means knowing a lot about substances, what the system needs, and the rules everyone follows. This detailed guide will help you think about the main points. It makes sure your project goes well and does what you expect.

Understanding Pipe Fittings and Their Importance

Pipe fittings are key parts. They link, manage, or change the path of liquids, gases, or other things moving through pipes. They help the system run well. They stop leaks. They keep everything strong under different situations. Bad choices can cause breakdowns, expensive fixes, or dangers. This makes picking the right ones very important for a good result.

Why Choosing the Right Pipe Fittings Matters

The correct pipe fittings help with:

- System Performance:Good matches make flow and pressure better. This lowers energy bills.

- Longevity:Strong fittings handle rust, high force, and heat shifts. This makes the whole thing last longer.

- Safety:Tight and tough fittings stop dangerous leaks or breaks. This follows safety rules.

- Saving Money:Picking lasting, matching parts lowers upkeep and swap costs.

Key Factors in Choosing Pipe Fittings

To pick the proper pipe fittings for your job, think about these things: what they’re made of, how big they are, if they work with your system, and how good they are. Each one is key to making your pipe network do what it should.

1. Material Selection

What your pipe fittings are made from sets how long they last, if they fight rust, and if they’re right for certain jobs. See the table below comparing common substances:

| Substance | Main Features | Top Uses |

| Copper | Fights rust, lasts long, handles high force | Hot/cold water tubes, heating and cooling gear |

| PVC | Light, fights chemicals, cheap | Cold water lines, drain systems |

| PEX | Bends easily, fights rust, simple to put in | Drinking water systems, small areas |

| Galvanized Steel | Tough, long-lasting, handles weather | Factory systems, high-force lines |

| Cast Iron | Very strong, built heavy, lasts a very long time | Sewage and drain systems |

Things to Think About for Material

- Surroundings:For dirty water or places with harsh chemicals, pick things like PVC or PEX. They resist breaking down.

- Heat and Force:Copper and cast iron are best for very hot or high-force systems. This includes heating and cooling or fire safety setups.

- Cost:PVC and PEX often cost less at first. Copper and cast iron might cost more upfront but work much longer.

2. System Compatibility

Your pipe fittings must work with your current or planned pipe network. Think about this:

- Job Type:Homes, shops, or factories have different needs. Fire safety systems might need grooved fittings. An example is the Vicast Grooved Mechanical Cross (XGQT18). It makes safe, leak-proof joins.

- Pipe Substance:Make sure the fittings match the pipe stuff. This stops rust caused by electricity or join problems.

- Following Rules:Fittings should meet rules like ISO6182, AWWA C606, or GB 5135.11. This makes them reliable and keeps you within the law.

3. Sizing and Specifications

Finding the correct size for pipe fittings is vital. It keeps flow and pressure right. Wrong sizes cause problems or breakdowns.

How to Find the Right Size

- Know Area Rules:Learn local pipe size rules. They change by place.

- Figure Flow and Force Needs:Count the taps, machines, or outlets in your system. This tells you the flow speed and force needed.

- Pick the Right Width:Match the fitting width to the pipe. This makes a smooth fit and good work.

For example, the Vicast Grooved Mechanical Cross (XGQT18) comes in sizes from 2″ to 10″ (DN50 to DN250). This makes it useful for many job sizes.

4. Quality and Durability

Good fittings are needed for long-term work. Look for fittings that are:

- Rust-Resistant:Choosing galvanized material for the pipe fittings during process can reduce the risks of rusting and damage.

- Checked for Rules:Make sure fittings meet rules like ASTM A536 or ASTM A395. This means they are strong and dependable.

- Tested to Last:Pick fittings that go through tough quality checks. Vicast fittings are made very carefully. They are tested for force and heat strength.

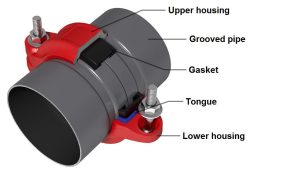

5. Ease of Installation

Fittings like grooved couplings make putting things in simple. This lowers worker costs and job time. Grooved fittings, like Vicast offers, allow fast, safe joins. You don’t need welding or tricky tools. This is great for jobs on tight timetables.

Types of Pipe Fittings and Their Applications

Different fittings do specific jobs in a pipe network. Here’s a look at common ones and what they do:

- Couplings:Link two pipes to make them longer or join different stuff.

- Elbows:Change flow direction at angles (like 90° or 45°) to go around corners.

- Tees and Crosses:Split or mix flow. The Vicast Grooved Mechanical Cross does this for multiple directions.

- Reducers:Link pipes of different widths. This keeps flow working well.

- Caps and Plugs:Close pipe ends to stop leaks or dirt getting in.

Rigid vs. Flexible Couplings

- Rigid Couplings:Give a firm, unmoving join. This is best for high-force systems like fire safety.

- Flexible Couplings:Allow a little movement. This lowers stress in systems with shaking or heat growth.

Vicast’s grooved couplings, for example, offer both rigid and bendable choices. This fits many job needs.

About Vicast: Your Trusted Pipe Fittings Supplier

Vicast is a brand under Hebei Jianzhi Foundry Group Co., Ltd. It has led in making pipe fittings since 1982. With over 40 years of knowledge, Vicast makes top grooved fittings. This includes the XGQT18 Grooved Mechanical Cross. It is made to last and be exact. Vicast works from a huge 1.4 million square meter place. It has 4,500 workers and over 350 tech experts. Vicast follows strict quality rules like ISO 9001 and ISO 14001. Their goods meet world rules (like ISO6182, AWWA C606). They sell in over 100 countries. This makes Vicast a solid partner for your plumbing and factory jobs.

Consulting Professionals for Optimal Results

This guide gives a strong start. But talking to a licensed plumber or industry expert is very helpful. These people can look at your job’s special needs. They can suggest suitable fittings. They make sure you follow local laws. Working with trusted suppliers like Vicast gets you top goods and expert help. This makes your job go faster.

Conclusion

Picking the proper pipe fittings for your job has many steps. You must think about substances, system fit, sizing, and quality. Know what your job needs. Pick fittings that follow industry rules. Then you get a dependable, effective, and money-saving pipe network. Vicast’s new grooved answers offer a reliable choice. They have decades of know-how behind them. This works for jobs of any scale. Make smart choices, ask experts, and work with trusted suppliers. This leads to success for years.

FAQs

What factors should I consider when choosing the right pipe fittings for my project?

Think about substance fit, system demands, pipe size, and quality rules. Make sure fittings match your pipe stuff to avoid rust. They must handle pressure and heat needs. They should follow rules like ISO6182 or AWWA C606.

How do I know if grooved fittings are suitable for my project?

Grooved fittings, like Vicast’s XGQT18 Mechanical Cross, are great for jobs needing fast setup, long life, and leak-proof joins. They fit heating and cooling, fire safety, and factory systems. This is extra true where high force or rust fighting is needed.

What is the difference between rigid and flexible pipe fittings?

Rigid fittings give a fixed, steady join for high-force systems. Bendable fittings allow a little movement. This makes them good for systems with shaking or heat growth. Picking the right type depends on your job’s special needs.

Why is material selection important when choosing pipe fittings?

Picking the substance affects how long it lasts, if it fights rust, and if it works with your system. For example, Galvanized surface-treated trench pipe fittings are suitable for coastal areas, especially in Australia, the Middle East and South America, where epoxy resin surface-treated trench pipe fittings are widely used. Choosing the right stuff means it works well for years. It lowers fix costs.

How can Vicast help with choosing the right pipe fittings for my project?

Vicast offers top grooved fittings, like the XGQT18 Mechanical Cross. They have over 40 years of know-how. Their goods meet world rules. Their tech team gives answers made for you. This makes sure your job succeeds.