Fire protection systems are the backbone of building safety. Picking the best parts makes a real difference. When linking pipes in these vital systems, the grooved mechanical cross really stands apart. It’s dependable, simple to put in, and made tough to handle pressure. This piece explores the top five plus points of using a grooved mechanical cross in fire protection setups. We’ll use real examples and industry knowledge. Whether you handle building work, design systems, or manage properties, you’ll see why this connector belongs in your next job.

What Is a Grooved Mechanical Cross?

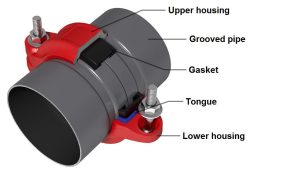

Before we get to the good parts, let’s explain what this is. A grooved mechanical cross is a pipe part. It joins four pipes at a meeting point. It makes a solid, leak-free connection. Unlike older welded or threaded parts, grooved setups use a clamp method. This clamp locks into special cuts on the pipe ends. This design, like the Vicast® Grooved Mechanical Cross (XGQT18), is built for demanding, high-pressure places. It also meets strict rules like ISO6182 and AWWA C606.

Imagine a packed business building—a hotel, medical center, or tall office block. Fire sprinklers must send water fast and reliably in a crisis. That’s where the grooved mechanical cross does well. It offers a strong answer for tricky pipe layouts. Now, let’s see why it’s such a smart pick.

Benefit 1: Faster and Easier Installation

Time matters greatly on any building spot. The grooved mechanical cross cuts setup time a lot versus welding or threading. How? It doesn’t need special skills or big tools. Workers just make grooves on the pipe ends. They line up the cross. Then they lock it with a clamp. Finished. A project review from the National Centre for the Performing Arts in Beijing shows this well. Finished in 2007, grooved setups saved weeks on the pipe work plan. Covering 165,000 m², every second counted.

Here’s why this counts for fire protection setups:

- Less worker expense:Fewer hours spent setting up means lower costs.

- No hot work passes needed:Unlike welding, grooved setups don’t need open fire. This makes them safer and simpler to use in tight spots.

- Very little stoppage time:For updates in working buildings, like hospitals, quick setup cuts disruption down.

I once talked with a builder who really liked grooved parts. His crew used them updating a 30-floor office building. He said they finished in half the time welded joints would have taken. That’s the actual effect we mean.

Benefit 2: Superior Reliability in High-Pressure Systems

Fire protection setups face huge pressure—really. A grooved mechanical cross, like Vicast’s XGQT18, is made to cope. Built from bendable iron (ASTM A536, Grade 65-45-12), these parts handle temps from -20°F to 180°F (-29°C to 82°C). They also manage high-pressure states without breaking or leaking. This strength is key for fire sprinklers. A single fault could be disastrous.

Think about the CITIC Tower in Beijing. This giant stands 528 meters tall. Finished in 2018, its fire protection setup depends on grooved parts. They make sure water moves smoothly to every floor. The stiff plan of the grooved mechanical cross stops shifting at the joint. This lowers leak danger over years. Plus, the exact machining gives a close seal. This holds even under the shakes common in big structures.

- Bendable iron build:Fights breaking under pressure and wild heat changes.

- Precision grooved plan:Gives a leak-free seal, even in shaky spots.

- Follows ISO6182:Matches worldwide rules for fire protection dependability.

Benefit 3: Cost-Effective Long-Term Solution

Let’s discuss money. Grooved mechanical crosses might cost a bit more upfront than simple parts. But they save money later on. How? Their toughness cuts upkeep and swap costs. Unlike welded joints that can rust, or threaded parts that loosen over time, grooved setups stay tight and working for decades.

Look at the Beijing South Railway Station. This big hub covers 320,000 m². Updated in 2008, its fire protection setup used grooved parts. They handled the complex pipe grid. Ten years later, checks showed very little wear. This saved big money on possible fixes. For property holders, this means:

- Lower upkeep costs:Fewer checks and fixes over the setup’s life.

- Longer use time:Grooved parts often last longer than the structures they’re in.

- Easy growth:Simple to change or add to setups without big reworks.

A building manager I know once told me how a grooved setup saved their money during a redo. They didn’t tear out old pipes. They just added new sections with grooved crosses. That’s flexibility old ways can’t match.

Benefit 4: Enhanced Safety for Fire Protection

Safety can’t be skipped in fire protection. A grooved mechanical cross boosts setup trustworthiness. It cuts failure risk under strain. Its plan lowers weak spots. This makes sure water gets to sprinklers when it matters most. The Suzhou Subway Station relies on grooved parts. With 350 km of lines and 1.78 million daily riders, it keeps its fire stop setup ready.

What makes it so safe?

- Shake fighting:The stiff clamp takes hits from building moves or quakes.

- Rust fighting:Made from top materials, these parts fight decay, even in wet places.

- No fire setup:Removes fire dangers during work. A big help in busy city jobs.

I’m not a designer, but I’ve seen enough fire setup tests. One leak can ruin a sprinkler setup. Grooved mechanical crosses give you calm knowing the setup will work when needed.

Benefit 5: Eco-Friendly and Sustainable Design

Being green isn’t just talk—it’s key. Vicast’s grooved mechanical crosses use up to 98% reused steel. This shrinks the carbon mark versus new iron ore parts. The firm’s push for the reuse circle means these parts can be recycled when done. This cuts waste down. For jobs seeking green stamps, like LEED, this is a win.

The Chengdu International Finance Square used Vicast’s grooved parts. This huge 760,000 m² zone finished in 2014. It met its green aims. By picking reused stuff, the job cut its nature harm without losing power. Plus, the water-smart making at Vicast’s plants ensures little resource waste.

- 98% reused steel:Cuts carbon output versus new stuff.

- Recyclable when done:Backs the reuse circle, shrinking trash piles.

- Water-smart making:Lowers nature harm during building.

Vicast: Your Trusted Grooved Mechanical Cross Supplier

For grooved mechanical crosses, Vicast leads. Started in 1982, Hebei Jianzhi Foundry Group Co., Ltd. has over 40 years making top pipe parts. With a huge 1.4 million m² plant and 4,500 workers, including 350 tech experts, Vicast gives exactness and trust. Their grooved mechanical crosses, like the XGQT18, meet tough rules (ISO6182, AWWA C606). Big jobs like the Beijing Olympic spots and Canton Tower trust them. Vicast’s push for new ideas, quality, and being green makes them the top pick for fire protection setups worldwide.

Conclusion

The grooved mechanical cross is more than a pipe part—it’s a wise buy for fire protection setups. From quicker setup to long-term money saving, better safety, and earth-kind design, it fits modern building jobs perfectly. Whether you’re fitting up a tower like the CITIC Tower or a busy hub like the Suzhou Subway Station, this part gives results you can count on. Vicast’s know-how and proven record make it simpler than ever to add these gains to your next job. Ready to make your fire protection setup quicker, safer, and cleaner? The grooved mechanical cross is the path to take.

FAQs

Why choose a grooved mechanical cross over welded fittings for fire protection systems?

Grooved mechanical crosses go in faster. They need no welding. They also cut leak chances. They’re a great fit for fire protection setups because they handle high pressure and shakes. This ensures water flows reliably in emergencies.

How does a grooved mechanical cross improve installation time?

It uses an easy clamp setup. This needs no special tools or flames. For instance, jobs like the National Centre for the Performing Arts saved weeks on setup times using grooved mechanical crosses.

Are grooved mechanical crosses environmentally friendly?

Yes! Vicast’s grooved mechanical crosses use up to 98% reused steel. This lowers carbon output. They’re also recyclable when done, backing green building ways.

Can grooved mechanical crosses handle extreme conditions?

Totally. Built from bendable iron, they work in temps from -20°F to 180°F. They fight decay and shakes. This makes them perfect for tough fire protection setups.

Where can I find a reliable supplier for grooved mechanical crosses?

Vicast, with over 40 years in the field, is a trusted source. Their parts meet global rules. Big jobs like the Beijing Olympics spots used them. See www.cnvicast.com for more info.