Sick of pricey pipeline fixes? Learn how grooved fittings can change your retrofit projects! They cut setup time in half, stop leaks, and handle pressures up to 363 psi. This easy guide shows why workers are dropping welding for this cool fix. It’s making heating, cooling, fire safety, and factory systems better all over the world.

Why Should You Retrofit Aging Pipelines with Grooved Fittings?

Old pipelines cause lots of trouble. They leak, work poorly, and can be unsafe. Fixing them up is super important to keep them working right and meeting today’s rules.

Benefits of Grooved Fittings in Pipeline Retrofitting

Grooved fittings bring tons of perks for fixing pipelines. They’re built for quick setup, which saves money and time compared to old ways. These fittings make a tight, no-leak connection that can take big pressure and heat. Plus, grooved fittings work for lots of jobs, like heating, cooling, fire safety, and factory systems. Their strong build keeps them going strong, even in tough spots.

Challenges of Traditional Pipeline Retrofitting Methods

Old-school ways of fixing pipelines often use welding or screwing pipes together. These take a lot of time and hard work. They need special skills and tools, which makes projects cost more. Also, welding adds heat that can mess up some materials or coatings. Screwed connections might leak over time if they wear out or aren’t put in right.

How Do Grooved Fittings Work in Pipeline Retrofitting?

Grooved fittings make fixing pipelines way easier. They don’t need fancy tools or tons of prep work.

The Mechanism Behind Grooved Fittings

Grooved fittings join two pipe ends with a simple system. A groove gets cut near the pipe’s end. Then, a coupling fits snugly around it. You tighten the coupling with bolts or clamps. This makes a strong seal that stops leaks. It also lets the pipe move a bit if heat or shaking happens.

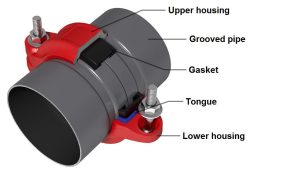

Key Components of a Grooved Fitting System

A grooved fitting system has these parts:

- Couplings: They link two pipe ends and keep things tight.

- Gaskets: These sit inside the coupling to stop water from leaking.

- Bolts and Clamps: They pull the coupling tight around the pipe ends.

- Pipe Ends with Grooves: The grooves let the coupling grab on without slipping.

Products like the Vicast Adaptor Flange (XGQT13) give solid fixes for joining pipes in heating, cooling, fire safety, and factory setups.

What Are the Steps to Retrofit Pipelines Using Grooved Fittings?

Fixing pipelines with grooved fittings takes a few steps to make sure everything works great.

Preparing the Existing Pipeline for Retrofitting

Inspecting and Cleaning the Pipeline

Before you start, check the pipeline for damage or rust. Clean the pipe ends well to get rid of dirt or junk. This helps the grooved fittings make a tight, no-leak seal.

Measuring and Marking for Installation

Getting measurements right is super important. Mark the pipe ends where grooves will go. This makes sure everything lines up nicely during setup.

Installing the Grooved Fittings

Aligning and Securing the Components

Line up the grooved pipe ends carefully. Put the coupling over them. Make sure all parts are in the right spot before tightening bolts or clamps.

Testing for Proper Fit and Seal

After you’ve tightened everything, test the system for leaks. Add pressure slowly. Check all connections to make sure they’re snug and safe. The Vicast Flexible Grooved Coupling (XGOT02) keeps a no-leak fit, even with high pressure.

How Can Vicast Help as a Reliable Supplier of Grooved Fittings?

Vicast is a trusted name for pipeline fixes. They’ve got years of know-how and cool ideas.

Overview of Vicast’s Expertise in Pipeline Solutions

For over 43 years, Vicast has made top-quality products across all 34 regions in China. They’ve worked on big projects, like spots for the Beijing Olympics. This shows they’re serious about doing great work.

Why Choose Vicast for Your Retrofitting Needs?

Vicast has lots of grooved fittings built to last and set up easily. Their products follow global rules like ISO6182 and AWWA C606, so they work well in tough spots. Whether you need the Vicast Adaptor Flange (XGQT13) or a mechanical cross, Vicast has what you need for your project.

What Are Common Mistakes to Avoid During Retrofitting?

Fixing pipelines with grooved fittings is quick and trusty, but some slip-ups can mess things up. Knowing these mistakes helps make setup smooth and keeps things working for a long time.

Overlooking Proper Inspection Procedures

Checking the pipeline well is a must. Skipping this can miss damage or rust, which hurts the system. Before you start fixing, look over the pipeline carefully. Clean off any dirt, rust, or junk from pipe ends. This makes sure grooved fittings seal tight with no leaks.

Also, not measuring right can cause trouble. If you don’t mark pipe ends exactly for grooves, parts might not line up. Taking careful measurements is a key step you can’t skip.

Misalignment Issues During Installation

Not lining up grooved fittings right is another common goof. This can lead to leaks or a system that doesn’t work well. When setting up grooved fittings, make sure all parts are in the right place before tightening bolts or clamps. If grooves on pipe ends aren’t even or the coupling isn’t sitting right, you’ll have problems.

Testing after setup is super important too. Slowly add pressure and check all connections for leaks. This helps catch issues early, so you don’t face big fixes later.

Ensuring Efficient and Reliable Pipeline Retrofitting with Grooved Fittings

Grooved fittings are a smart way to fix old pipelines. They make setup simple and keep systems working well. They skip welding or screwing, which saves time and money. Plus, they make a strong connection that handles big pressure and heat.

Products like the Vicast Flexible Grooved Coupling (XGOT02) are great for joining pipes in heating, cooling, fire safety, and factory systems. They’re built tough and easy to use, keeping things leak-free even in hard conditions.

Vicast’s long experience makes them a go-to name in the field. Their grooved fittings meet big rules like ISO6182 and AWWA C606. They work great for all kinds of jobs.

FAQs About Retrofitting Pipelines with Grooved Fittings

Q1: What Makes Grooved Fittings Good for Old Pipelines?

Grooved fittings are awesome for old pipelines. They’re easy to set up without welding or screwing. Their design lets pipes move a bit with heat or shaking, so they last long, even in older systems.

Q2: How Long Does It Take to Fix a Pipeline with Grooved Fittings?

It depends on the pipeline’s size and how tricky it is. But grooved fittings cut setup time a lot compared to old ways. Their simple system makes things faster.

Q3: Can Grooved Fittings Handle High-Pressure Systems?

Yup! Grooved fittings like those from Vicast are made for high-pressure jobs. For example, the Vicast Adaptor Flange (XGQT13) keeps a no-leak connection at pressures up to 363 psi.