Find out the great perks of grooved couplings in building work! They speed things up, stay strong for years, and are kind to the planet. These clever fittings are making pipe connections better. See why workers pick them and how Vicast’s awesome products can make your next project shine.

Why Are Grooved Couplings Popular in Modern Construction?

Grooved couplings are a big hit in today’s building scene. They’re simple to use, tough, and fit lots of jobs. These neat systems make hooking up pipes easy. Folks love them because they fix issues like slow work, leaks, and fitting into tricky spots.

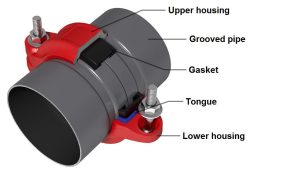

Key Features of Grooved Couplings

Grooved couplings are famous for their smart build and sturdy make. They form a snug, no-leak link that can take lots of pressure and heat. Take the Vicast 11.25° and 22.5° grooved pipe fitting elbows, for example. They meet rules like ASTM A536 and ASTM A395. So, they keep working great for ages, even in rough places. Top-notch materials help them fight wear, making them perfect for shops and offices.

Applications of Grooved Couplings Across Industries

Grooved couplings are really handy. They pop up in all sorts of work. You’ll see them in heating and cooling setups, fire safety gear, and factory pipes. Stuff like the Vicast Mechanical Tee Threaded or Grooved Mechanical Cross gives solid answers. They’re a breeze to put in and do their job well. That’s why they’re great for projects needing trusty pipes.

How Do Grooved Couplings Improve Installation Efficiency?

A huge plus of grooved couplings is how they make setup quick. Old pipe-joining tricks, like welding, need tons of time and hard work. Grooved systems keep things way easier.

Faster Installation Compared to Traditional Methods

Grooved couplings are made for fast fitting. You don’t need special gadgets. This saves a bunch of time compared to welding or twisting pipes together. For instance, the Vicast Adaptor Flange is built for simple setup. But it still holds tight under big pressure.

Reduced Labor and Equipment Costs

Grooved couplings cut costs. They don’t call for big tools or super-skilled workers. Their easy design means you need less stuff to get the job done. This makes them a wise pick for large projects.

What Makes Grooved Couplings Durable and Reliable?

Being strong and trustworthy is super important for pipe systems. Grooved couplings rock at both. Their solid make means they stick around for a long time in all kinds of settings.

Enhanced Leak Prevention with Secure Couplings

Keeping leaks away is a major win for grooved couplings. Their tight grips stop water or air from sneaking out. For example, Vicast’s rigid grooved couplings lock in a no-leak fit, even with heavy pressure. This is key for systems that must stay safe and solid.

Resistance to Pressure and Temperature Variations

Grooved couplings can deal with wild swings in pressure and heat. Their materials and build let them thrive in harsh spots. Products like the Vicast Flexible Grooved Coupling handle temps from -20°F to +180°F (-29°C to +82°C). They also take on pressures up to 363 psi.

Can Grooved Couplings Help with Maintenance and Repairs?

Checking and fixing old-school pipe systems can be a pain. Grooved couplings make those jobs much simpler.

Simplified Inspection and Maintenance Processes

Grooved systems come in pieces. This makes checking or fixing them easy. You can pull parts apart fast without wrecking the whole setup. That saves time and work.

Easy Replacement of Components Without Major Disruptions

When fixes are needed, grooved couplings are really useful. You can switch out bits without shutting everything down. This is awesome for places that need to keep going.

Why Choose Vicast Products?

Vicast has been crafting cool grooved pipe fittings for over 40 years. They’ve tackled massive projects in China, like spots for the 2008 Beijing Olympics. Their website lists loads of items, like mechanical tees, flanges, couplings, and elbows. Vicast makes sure buyers get tough tools for their work.

Whether it’s sprucing up famous sites like the Canton Tower or shaping city views, Vicast means quality. Going with Vicast means choosing gear that’s strong, quick to use, and lasts forever.

How Do Grooved Couplings Support Sustainable Construction Practices?

Grooved couplings are shaking up building work by helping the earth. Their make and features shrink waste and save power. They’re a super choice for jobs that want to go green.

Reduction in Material Waste During Installation

Grooved couplings save stuff. Old ways of joining pipes, like welding, toss out lots of material. Grooved systems skip those steps. Their clever build makes links fast and right. So, less stuff gets wasted.

Also, their piece-by-piece setup lets you tweak or swap things easily. You don’t need to rip out whole chunks. This cuts waste and keeps pipes going longer, which is great for eco-friendly building.

Contribution to Energy-Efficient Systems

Grooved couplings help save power too. Their no-leak design keeps heating and cooling gear running smoothly. This lowers energy waste. For example, Vicast’s Flexible Grooved Coupling takes on high pressure and heat while staying snug. That means fewer repairs and less power used over time.

Plus, grooved systems fit well with new power-saving tools. They slide into renewable energy setups or modern cooling gear. This helps create greener buildings.

Why Choose Vicast as Your Trusted Supplier for Groove Fittings?

When picking a supplier for grooved pipe fittings, Vicast stands tall. Their long know-how and love for quality make them perfect for any job.

Overview of Vicast’s Expertise in the Industry

Vicast has been at it for over 40 years in China. They’ve pitched in on huge projects, like the 2008 Beijing Olympics and the Canton Tower. This proves they can tackle all sorts of tasks. Their product lineup has grooved couplings, mechanical tees, flanges, and elbows. These suit heating, fire safety, and factory systems.

Commitment to Quality and Customer Satisfaction

Vicast is all in on making top stuff. Their fittings hit hard standards like ASTM A536 and ASTM A395. So, they’re tough and trusty, even in rough spots. Their smart designs stop leaks, which makes systems work better.

Vicast’s operations aim for happy buyers. They give support and custom fixes. Picking Vicast means teaming up with a group that cares about your wins.

Conclusion: Embracing the Benefits of Grooved Couplings in Construction

Grooved couplings offer loads of benefits for today’s building needs. They shrink waste, save power, and hold up for years. With solid suppliers like Vicast giving great grooved pipe fittings, using these systems is a bright idea. They’re ideal for projects wanting strength, speed, and planet-friendly ways.

Frequently Asked Questions About Grooved Couplings

Q1: Are grooved couplings okay for high-pressure systems?

Yup! Grooved couplings are made for high-pressure tasks. Take Vicast’s Flexible Grooved Coupling—it handles up to 363 psi. That’s perfect for factories or fire safety gear.

Q2: Do grooved couplings work with all kinds of pipes?

For sure! Grooved couplings match with steel, ductile iron, and PVC pipes. This makes them great for tons of projects.

Q3: How much care do grooved couplings need?

Hardly any! Their tough build means they don’t need much upkeep. Quick checks keep them running fine. If you need to swap something, it’s fast and simple.