Wanna figure out which pipe fittings can take the pressure in your system? Let’s jump into how picking materials, shaping designs, and following rules make fittings super tough. Choosing the right fitting is a big deal for keeping things safe and running smoothly.

What Makes Pipe Fittings Tough Against Pressure?

Pipe fittings are super important in any pipe setup. They gotta be strong to handle pressure. This keeps everything safe and working well. Here’s what decides how much pressure a fitting can take.

The Stuff They’re Made Of

What a fitting is made from changes how strong it is. Metals like stainless steel, carbon steel, and ductile iron are really popular. They’re tough and don’t bend or crack easily. This lets them handle big pressure without leaking. Plastics or mixed materials get used too. But they’re not as strong unless they’re built special for hard jobs.

Wall Thickness and Shape

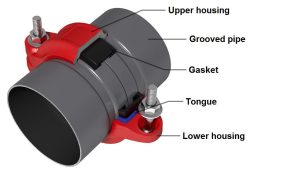

Thicker walls help fittings take more pressure. How they’re shaped matters a lot too. Stuff like curves, extra supports, or how they connect—like grooved, threaded, or welded—makes a difference. For example, our rigid grooved coupling is a great pick for joining pipes in things like HVAC, fire systems, or factories. It’s built strong, goes in easy, and stays tight under high pressure or heat.

Heat and Outside Conditions

Hot or cold weather can make materials stretch or shrink. This changes how much pressure they can hold. Things like chemicals or sunlight can wear out some materials over time. So, you need to pick fittings that fit the heat and the place they’ll be used.

How Do Metal Pipe Fittings Handle Pressure?

Metal fittings are awesome for high-pressure jobs. They’re super strong and last forever.

Common Metals Used

Stainless Steel

Stainless steel is great at fighting rust. It stays tough in all kinds of temps. It’s perfect for clean jobs, like in food or medical places, or spots with yucky chemicals.

Carbon Steel

Carbon steel is really strong and costs less than stainless steel. But it might need a coating to stop rust in rough spots. It’s used a lot in big factory jobs with high pressure.

Brass and Copper Alloys

These metals are pretty good at stopping rust. They’re easy to shape but can’t take as much pressure as steel. They’re used for smaller, less heavy jobs.

Why Metal Fittings Are Great for High Pressure

Metal fittings can handle super high pressure without breaking. They’re perfect for systems where pressure goes up and down a lot. They don’t wear out quick. Plus, they follow strict rules from groups like ASTM or ISO. That means you can trust they’re good quality.

Are Plastic Pipe Fittings Okay for High-Pressure Jobs?

Plastic fittings have neat perks, like not rusting and being super light. But they’re not always great for high-pressure stuff.

Types of Plastic Materials

PVC (Polyvinyl Chloride)

PVC is cheap and easy to use. You see it in home plumbing or farm water systems. But it can’t handle super hot temps or really high pressure.

CPVC (Chlorinated Polyvinyl Chloride)

CPVC is like PVC but better for hot water. It can take more heat and a bit more pressure. It’s good for warm water setups but not for really tough jobs.

PEX (Cross-linked Polyethylene)

PEX is bendy and doesn’t get clogged with junk. It’s awesome for home water lines but only for low or medium pressure.

Limits of Plastic Fittings

Plastic can get weak and brittle from sunlight or harsh chemicals after a while. It might bend or break if there’s too much pressure or heat. So, you gotta make sure plastic fits your job. It’s cool for some things but not for heavy-duty systems.

Can Composite Materials Handle Pressure?

Composite fittings mix things like resins and fibers to get neat features, like being light but still tough.

What’s Neat About Composite Fittings

These fittings are light but strong enough for medium-pressure jobs. They don’t rust and don’t carry heat like metals. They’re great for special jobs where weight or staying safe from chemicals matters more.

How Composites Stack Up Against Metal and Plastic

Composites are tougher than plastics but not as strong as metals like ductile iron or stainless steel for super high pressure. They’re awesome for jobs where you need to save weight or avoid chemical damage more than max strength.

What Rules Keep Fittings Safe for Pressure?

There are big rules to make sure pipe fittings are safe and work right everywhere.

ANSI, ASTM, and ISO Rules

Groups like ANSI, ASTM, ISO, and AWWA C606 make rules for stuff like size, materials, and how much pressure fittings can take. They test things like burst pressure to make sure they’re safe. For example:

- Material standard: ASTM A536, Grade 65-45-12; ASTM A395, Grade 65-45-15

- Design standard: ISO6182, AWWA C606

Why Following Rules Is a Big Deal

Fittings that follow these rules are tested to be safe. This is really important for high-pressure systems. A bad fitting could burst and cause trouble, like leaks or even hurting people. Always look for labels that show the fitting meets these rules.

Why Does the Right Material Matter for Safety?

Picking the right material isn’t just about doing a good job. It’s about keeping things safe for a long time.

Risks in Low vs. High-Pressure Systems

Low-pressure systems might be okay with small problems. But high-pressure systems need perfect fittings. A weak fitting could leak or pop, which might hurt people or wreck stuff.

Staying Tough and Easy to Fix

Strong materials last longer and don’t need fixing as much. For example, our rigid grooved coupling is made with awesome materials. It’s tough, trustworthy, and built to keep going for any job that needs solid work.

How Does Vicast Make Sure Its Fittings Are Awesome?

As jobs like HVAC or fire systems get trickier, quality is super important. Vicast stands out by making really great products.

Using Great Materials and Tough Tests

Vicast’s products follow strict rules like ASTM A536 Grade 65-45-12 and ISO6182. They’re tested to handle hard jobs in all kinds of weather, from -20°F to +180°F. This makes them really dependable.

Products for All Kinds of Pressure Jobs

Vicast has tons of products, like Grooved Couplings, Mechanical Tees, Mechanical Crosses, and Flanges. They’re built to handle up to 363 psi, depending on size (DN25–DN300). They work for all sorts of jobs, from tiny to huge.

Building Trust with Customers

Vicast’s fittings are used in big projects, like the Beijing Olympic venues. They’ve shown they work great in cities and towns all over China. People trust Vicast because it always delivers solid results.

FAQs About Pipe Fitting Strength

Q1: What’s the toughest material for pipe fittings?

Metals like stainless steel or ductile iron are super strong. They handle high pressure and last a long time.

Q2: Can plastic fittings work in big industrial jobs?

Yup, but only for some jobs. CPVC or strong plastics can handle medium pressure. But they’re not great for super hot or heavy-duty setups.

Q3: How do I pick the right fitting material?

Think about pressure, heat, the kind of liquid, sunlight or chemical exposure, and rules like ASTM or ISO. Check specs from trusted brands like Vicast to make sure it fits your job.