Si alguna vez has puesto el mismo dibujo frente a dos fundiciones y has obtenido dos números muy diferentes, ya has encontrado el verdadero problema: controladores de costos de fundición rara vez viven en el artículo de línea que todo el mundo espera. En fundiciones industriales, especialmente accesorios de tuberías y componentes de conexión ranurados, la cotización inicial es solo el comienzo de la historia. El objetivo aquí no es ahogarte en las especificaciones. Es para ayudarle a predecir el costo durante todo el ciclo de vida de una pieza, hacer preguntas de RFQ más limpias y establecer expectativas que no explotarán más tarde cuando la producción se realice.

Por qué dos citas de “la misma parte” pueden estar separadas entre un 30 y un 80%

Dos proveedores pueden mirar un dibujo y hacer suposiciones diferentes en silencio. Una tienda asume que "como fundido está bien" en una superficie que su conjunto realmente usa como sello. Otro supone que aceptará la inspección dimensional estándar, mientras que espera pruebas del 100%. Uno de los precios en más riesgo de proceso porque la geometría grita chatarra, mientras que los otros precios como si el rendimiento fuera perfecto.

El precio no es sólo matemática. El riesgo se traduce en dólares.

Aquí está la parte que muchos compradores pierden: esas suposiciones a menudo se remontan a una decisión tomada antes de que alguien hablara sobre el precio unitario: cómo se va a lanzar la parte en primer lugar. Si tu equipo todavía está pesando las rutas, empieza por: Elegir el proceso de fundición adecuadoEse paso tiende a resolver la mitad de las conversaciones “¿por qué esta cita es más alta?” antes de comenzar.

“El mismo dibujo” no es “el mismo trabajo”

Un dibujo no siempre comunica toda la historia de fabricación. Una sola nota como "máquina para encajar" puede significar un paso rápido para una alineación áspera, o puede significar múltiples configuraciones, herramientas más ajustadas y tiempo de ciclo más largo porque la superficie funcional real se encuentra detrás de esa nota.

Diferencias de citas generalmente provienen de estos predeterminados ocultos

Piense en la cotización como un conjunto de predeterminaciones que el proveedor llena: permiso de mecanizado, estrategia de puerta, nivel de acabado, plan de inspección, resistencia del embalaje y si el retrabalón se trata como una excepción o algo que sucederá de forma rutinaria. Tu RFQ controla esos valores predeterminados o pagas por ellos más tarde.

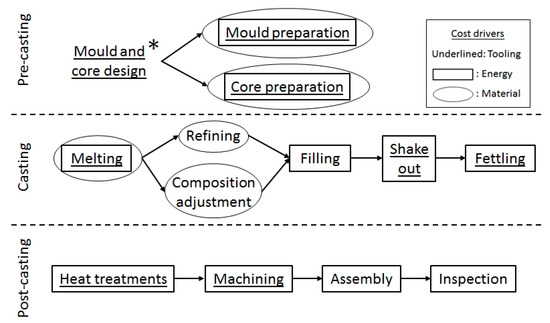

La pila de costos: a dónde va el dinero

El precio de la fundición parece sencillo cuando se resume como “trabajo metálico”. En la práctica, se comporta más como una pila, con cada capa reaccionando a su geometría, tolerancia y volumen.

El costo del material es más que “precio por kg”

El material es a menudo el número visible más grande, pero el conductor no es solo la aleación. También es el peso terminado versus el peso vertido. Si una pieza necesita puertas pesadas, elevadores grandes o material de mecanizado adicional para alcanzar la tolerancia de manera consistente, el metal vertido aumenta incluso cuando el peso terminado permanece el mismo. Esa brecha aparece en la tasa de rendimiento, la tasa de chatarra y la pérdida de fusión, tres cosas que los compradores no ven en una hoja de especificaciones.

Para el hierro dúctil y los trabajos relacionados con el montaje de tuberías, la tolerancia al peso importa de una manera muy práctica: las fundiciones más pesadas de lo necesario consumen tiempo de mecanizado, y las fundiciones más ligeras de lo necesario suponen riesgos, especialmente en las piezas relacionadas con la presión.

Costo de herramientas y patrones: la factura que no quieres repetir

La herramienta no es solo una tarifa inicial. Es un compromiso con una geometría. Si el diseño cambia después de cortar la herramienta, es posible que pague dos veces: una vez por la herramienta y otra vez por el orden de cambio que proviene de la herramienta que no coincide con la revisión actualizada.

En lotes más pequeños, la herramienta domina el costo unitario porque se amortiza en menos piezas. En largas carreras, la herramienta se convierte en un activo de estabilidad: menos sorpresas dimensionales, tiempo de ciclo más predecible y una producción más limpia cuando se necesita consistencia.

Mecanizado y tolerancia: el multiplicador silencioso

Los costos de mecanizado escalan con más que la superficie. El tiempo de instalación y la fijación a menudo son más importantes. Una pieza que necesita tres orientaciones en un molino, o una que requiere mantener la concentricidad entre las características internas, puede aumentar el costo incluso cuando la cantidad total de metal eliminado parece modesta.

El truco de un buen comprador es separar las “superficies funcionales” de las “superficies agradables de tener”. Si una superficie solo importa por la apariencia, trata de manera diferente en las especificaciones. De lo contrario, la fundición puede valorarla como una cara de sellado.

El post-procesamiento no es una cosa

“Después del tratamiento” puede significar un desbarbado rápido. O puede significar chorro más recubrimiento más protección de hilo más empaquetado estricto para que las piezas lleguen sin daño al borde. Cuando los compradores presionan por una cotización más baja, el post-procesamiento es a menudo donde los proveedores recortan. Aquí es donde comienzan las quejas más tarde.

Pruebas e inspección: costo como confianza

La prueba no es una casilla de verificación ceremonial. Cambia el flujo de trabajo. El aumento de la inspección aumenta la mano de obra, ralentiza el rendimiento y puede requerir accesorios adicionales o gestión de registros. Pero en muchos proyectos, tuberías de protección contra incendios, redes de HVAC o sistemas industriales, esos controles evitan fallas que cuestan mucho más que el programa de prueba.

Estimación del costo por complejidad de la pieza y tamaño del lote

La mayoría de los compradores no necesitan una fórmula perfecta. Necesitan una manera rápida de comprobar la sanidad de una cotización antes de que vaya a la administración.

Pequeño lote: su precio unitario está pagando por el aprendizaje

En la producción de bajo volumen, el precio unitario a menudo incluye el tiempo de configuración, el ajuste del proceso y una mayor concesión para el retrabalón. Si está ordenando unos pocos cientos de piezas, su mejor palanca generalmente no es negociar centavos en metal; Es asegurarse de que el dibujo comunique lo que importa y lo que no, y confirmar si la herramienta es lo suficientemente flexible para actualizaciones de revisión menores.

Volumen medio: el tiempo del ciclo y la chatarra comienzan a decidir todo

En el rango medio, los precios de la fundición comienzan a comportarse como la fabricación. Si un diseño crea puntos calientes de porosidad o zonas de contracción complicadas, una tienda puede necesitar controles de proceso más estrictos o la chatarra subirá. Cuando la chatarra sube, los proveedores o bien aumentan el precio, o lo comen, hasta que no pueden.

Gran lote: la consistencia se convierte en el verdadero "costo"

El alto volumen parece "piezas baratas". Pero en realidad son "piezas baratas solo si la línea se mantiene estable". Los factores de costo cambian a la vida útil del molde, la repetibilidad del accesorio y la velocidad de inspección. Un punto de deriva puede convertirse en miles de rechazos. Es entonces cuando los compradores se dan cuenta de que el precio no era el único número que importaba.

No hay punchline aquí. Sólo la realidad.

Conductores ocultos que la gente pierde hasta que la producción duele

Algunos costos no aparecen en una primera cotización. Aparecen como un problema de horario.

Opciones de rendimiento y agrupación

Cuando la geometría de una pieza forza la apertura pesada, o la trayectoria de flujo de metal es implacable, el rendimiento cae. Un menor rendimiento significa más metal vertido por buena parte, más tiempo de fusión y más manejo. También significa más variancia entre lotes, lo que a menudo desencadena una clasificación adicional.

Piezas "Parecen sencillas" que son caras de todos modos

Los accesorios de tuberías y componentes ranurados pueden parecer sencillos. Muchos no lo son. Un perfil de ranura que debe acoplarse de manera fiable, una superficie de sellado que no puede chatear durante el mecanizado, un hilo que debe medirse limpiamente cada vez, esos no son detalles cosméticos. Ellos crean trabajo.

Daños de embalaje y tránsito

Si envía a nivel mundial, la tasa de daños es un motor de costos. Puede convertir una "buena cotización" en una mala compra si los bordes se rompen, los recubrimientos se desgastan o los hilos llegan comprometidos y necesitan un nuevo trabajo.

Cómo hablar precio sin crear un mal bucle de RFQ

La forma más rápida de descarrilar una cita es negociar sin alinear lo que significa “hecho”.

Establecer la expectativa de que el costo está vinculado a las decisiones

Si su equipo necesita una tolerancia más estricta, trazabilidad completa o tratamiento superficial específico, dígalo por adelantado. De lo contrario, obtendrá una cotización baja basada en las suposiciones estándar del proveedor, luego los requisitos reales aparecerán más tarde y el precio “cambiará misteriosamente”.

Separar los costos únicos de los costos de funcionamiento

Cuando un proveedor le da el costo de herramientas más el costo unitario, tratelos como conversaciones diferentes. La herramienta se trata de la reducción de riesgos y la repetibilidad. El costo unitario se refiere al tiempo de ciclo, el rendimiento y la mano de obra. Si los agrupas, negociarás ambos mal.

Si necesitas bajar los costos, haz la pregunta correcta

"¿Puedes hacer un 10% menos?" es vago. “¿Qué especificaciones están impulsando el costo y qué podemos relajarnos sin arriesgar el rendimiento?” tiende a obtener una respuesta útil, especialmente si su pieza tiene superficies críticas y no críticas.

Los detalles de la RFQ que le dan una cotización precisa la primera vez

Una RFQ limpia no tiene que ser larga. Debe ser específico en los lugares que realmente mueven el costo.

Si desea una cotización que cumpla, incluya la revisión del dibujo y una breve nota sobre qué superficies son funcionales, qué volumen espera en un año, qué tamaños de lotes se ven, qué mecanizado se requiere (y dónde), qué pruebas o inspecciones se esperan, y cuáles son sus requisitos de embalaje si el daño crearía un nuevo trabajo a la llegada.

Las RFQ cortas no ahorran tiempo si producen precios inestables.

Donde Hebei Jianzhi Foundry Group Co., Ltd. encaja en la conversación de costes

La previsibilidad de los costos generalmente proviene de la escala, el control de procesos y un enfoque del producto que coincida con el caso de uso. Hebei Jianzhi Fundición Grupo Co., Ltd. Describe una larga historia de producción desde 1982 y una gran huella de fabricación, con mano de obra y recursos de ingeniería que apoyan una producción consistente en diversas especificaciones.

En el sitio de Vicast, el enfoque del producto se centra en accesorios de tuberías ranuradas (acoplamientos, tees mecánicos, cruces mecánicos y bridas ranuradas) utilizados en aplicaciones como protección contra incendios, HVAC, suministro de agua y sistemas de tuberías industriales. El sitio también señala las opciones de materiales como el hierro dúctil y destaca el valor práctico que tienden a preocupar a los compradores: instalación modular, facilidad de servicio y la capacidad de mantener la integridad del sistema sin soldadura o roscado.

Eso importa para el precio porque partes como estas no se compran como piezas de arte. Se compran como componentes del sistema. Cuando el cronograma de instalación es ajustado y el retrabalón de campo es costoso, la consistencia y el ajuste repetible a menudo valen más que un precio unitario ligeramente más bajo.

Conclusión

Buenas compras de fundición no se trata de “encontrar la fundición más barata”. Se trata de reducir el número de sorpresas después de que ya se haya comprometido con un horario. Las mejores cotizaciones son las que puedes confiar seis meses después, cuando el volumen cambia, las inspecciones se vuelven más estrictas o el primer envío ya está instalado en un sistema en vivo.

Si toma una cosa de esto: el costo de la pieza no solo está determinado por el metal. Está determinado por decisiones, algunas de ellas tuyas, algunas de ellas por defecto del proveedor. Cuando esas decisiones se alinean temprano, los precios se vuelven predecibles, y los precios predecibles son lo que hace que los proyectos se ejecuten a tiempo.

Preguntas frecuentes

¿Cuáles son los mayores factores de costo de fundición en los precios de fundición del mundo real?

Los principales impulsores son generalmente el peso vertido frente al peso terminado, la estrategia de herramientas, la complejidad de la configuración de mecanizado, los requisitos de postprocesamiento y el nivel de inspección o prueba requerido para apoyar la aplicación. En muchas cotizaciones, las hipótesis de inspección y mecanizado crean más variación que la materia prima.

¿Cómo puedo estimar el costo de fundición antes de enviar una RFQ?

Comience con el peso de la pieza y el volumen esperado, y luego pregúntese qué hace que la pieza sea “dura”: tolerancias ajustadas, múltiples caras mecanizadas, superficies de sellado, roscas, acabados especiales o niveles de inspección más altos. Incluso una evaluación aproximada de esos factores le dirá si es probable que una cotización sea estable o que cambie después de la revisión técnica.

¿Un mayor volumen siempre significa un menor precio unitario para fundiciones industriales?

No siempre. Un mayor volumen puede reducir el precio unitario cuando la estabilidad de la herramienta y el proceso ya están probados. Pero si la geometría crea riesgo de chatarra, o si los requisitos de calidad se endurecen a medida que el proyecto madura, el costo unitario puede aplanarse o incluso aumentar hasta que el proceso se controle.

¿Qué debo aclarar durante la negociación de precios para que la cotización no cambie más tarde?

Clarificar el alcance del mecanizado, las superficies funcionales, las expectativas de inspección/prueba, el tratamiento superficial, los requisitos de envasado y su probable cadencia de lotes. La mayoría de los “cambios de cotización” provienen de suposiciones ausentes en una de esas áreas, no de un proveedor que cambie de opinión.

¿Cómo establecer una expectativa razonable con los clientes cuando presionan por un precio de fundición más bajo?

Marco la conversación en torno a compromisos que no comprometan el rendimiento: relajar los requisitos de superficie no funcionales, simplificar el mecanizado donde no afecta al ajuste, alinear el nivel de inspección con el riesgo real y confirmar si una inversión en herramientas reducirá la chatarra y el retrabalón a largo plazo.