Trying to pick between rigid and flexible grooved couplings? This easy guide explains what makes them different. It shows where they work best. It helps you choose the right one for your pipes. Let’s jump in!

What Are Grooved Couplings and How Do They Work?

Grooved couplings changed piping big time! They’re faster. They’re more flexible. They save money compared to welded or threaded stuff. They make pipes easy to put together or take apart. That’s super handy for projects needing quick fixes or changes.

Basics of Grooved Pipe Connections

Grooved systems join pipes with special couplings. These clamp onto grooves near pipe ends. A gasket inside seals the pipes tight. No leaks! The housing adds a tough hold. No need for welding or threading. This cuts setup time and costs a lot. Grooved fittings are used in HVAC systems, fire sprinklers, factory water lines, and building pipes.

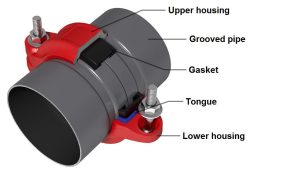

Parts of a Grooved Coupling System

Each system has:

- A rubber gasket for a no-leak seal

- A two-piece ductile iron housing that grabs the grooves

- Bolts and nuts to lock it tight

Pipes need roll-grooved or cut-grooved ends. They must match the maker’s rules exactly.

Why Grooved Connections Are Cool

Grooved couplings are super quick to set up. No welding or threading needed! They’re safer—no hot work permits. They make future changes easy. Plus, they handle pipe shakes, heat changes, or slight misfits. That’s really neat!

How Do Rigid and Flexible Couplings Differ?

Both rigid and flexible grooved couplings join pipes tight. But their insides decide how they work in different spots.

What Makes Them Different

Rigid couplings lock pipes super tight. They act like one big pipe. No moving or bending allowed. Flexible couplings let pipes wiggle a bit. Flexible grooved coupling XGOT02 handles 363 psi (2.5 MPa) and temps from -20°F to +180°F (-29°C to +82°C).

How They Work in Pipes

Holding Heavy Loads

Rigid couplings are super strong. They keep pipes lined up tight. They’re great when you need a solid setup.

Handling Shakes and Moves

Flexible couplings are champs at soaking up shakes. They work great where pipes move from vibrations or settling.

Lining Up Pipes

Flexible ones forgive small lineup mistakes. That’s a big help in tricky pipe layouts with lots of turns.

When Should You Pick a Rigid Coupling?

Rigid couplings are best when you need things super steady.

Best Spots for Rigid Couplings

Fixed Pipe Systems

In places like tall building risers, pipes are locked in place. Rigid couplings keep everything straight and strong.

Long, Straight Pipes

Pipes that don’t move or stretch love rigid couplings. They stay stiff over long runs. Our rigid grooved coupling is perfect for projects needing strength, trustiness, and long-lasting power.

Downsides of Rigid Couplings

Rigid ones don’t like movement. If temps change or the ground shakes, they might stress joints if you don’t plan right.

When Is a Flexible Coupling Better?

Flexible couplings bend where rigid ones can’t.

Where Flexibility Helps

Heat Changes

Pipes get bigger when hot and smaller when cold. Flexible couplings handle these shifts without breaking joints.

Shaky or Earthquake Areas

In places with quakes or big machines, flexible couplings soak up shakes. They stop joints from busting. They’re a simple, trusty, and cheap fix for lots of jobs.

Tricky Setups

In tight spots with lots of turns, flexible couplings make lining up pipes easier. They cut down on mistakes.

Can You Use Rigid and Flexible Couplings Together?

You bet! Mixing them can make your pipes strong and bendy at the same time.

Mixing in Big Systems

Designers use rigid couplings for straight parts. They put flexible ones near pumps or valves where pipes might move.

Balancing Strength and Wiggle Room

This mix keeps pipes steady but ready for shakes or heat changes. It’s a super smart plan!

Why Picking the Right Coupling Matters

Choosing rigid or flexible isn’t just a guess. It affects safety, work speed, long life, and cost.

How It Impacts Your System

Picking wrong can cause leaks or breaks. But grooved systems save 25–50% on costs in big projects. They work great too! Wrong groove depth can mess up seals, so check that!

Mistakes to Skip

Don’t use rigid where you need wiggle room. Don’t use flexible where you need rock-solid holds. Make sure grooves are deep enough for a good seal.

Why Grooved Couplings Are Super Cool

Grooved couplings make piping a piece of cake! They’re quick for school sprinklers or office HVAC. They handle factory shakes or earthquake zones. New designs are super easy to use. Vicast’s gear makes projects fast and fun!

Why Trust Vicast for Your Pipe Fittings?

Need great couplings? Vicast is a super awesome choice!

Vicast’s Quality and New Ideas

Vicast started in 1982. They’re a top maker of grooved fittings. With 4,500 workers and 350+ engineers in huge 1.4 million square meter factories, they follow ISO 9001 rules. They helped write national standards! With over 200 patents, they’re always thinking up cool stuff.

Vicast’s Products

Vicast has tons of fittings! Think Grooved Pipe Fitting Coupling, Mechanical Tee & Cross, elbows at 11.25° or 22.5°, and Grooved Flanges. They work for HVAC, fire sprinklers, water plants, and tough jobs.

Global Help

Vicast sells in over 100 countries. Their teams help from picking to setting up. They make sure your pipes work great everywhere.

Key Takeaways from This Comparison

Picking rigid or flexible grooved couplings depends on your job. Neither is better—they’re just different!

Matching Couplings to Jobs

Need steady pipes for long runs? Go rigid. Got pumps or shaky spots? Pick flexible. The right choice makes pipes work great in real life.

Rigid vs Flexible: It’s About the Job

Each fits different needs. Think about heat, shakes, or quakes before picking one.

Trust Vicast for Awesome Results

With 40 years of know-how and sales in 100+ countries, Vicast’s high-quality gear gives you peace of mind. Their stuff meets tough standards like ISO 9001.

FAQs About Rigid and Flexible Grooved Couplings

Q1: What’s the main difference between rigid and flexible grooved couplings?

Rigid ones lock pipes tight with no movement. Flexible ones allow a bit of wiggle for shakes or heat changes.

Q2: Are grooved couplings good for high-pressure jobs?

Some, like Vicast’s Flexible grooved coupling XGOT02, handle up to 363 psi. But most are for low or medium pressure, depending on design.

Q3: Do grooved systems need special tools?

Nope! Just torque wrenches and basic hand tools. This cuts tooling costs by 60–70%. It’s super easy!