Need to pick between pipe fittings and forged fittings? This easy guide breaks it down. It helps you choose the best for your pipe projects. Let’s dive in!

What Are Pipe Fittings and Forged Fittings?

Pipe fittings and forged fittings are super important! They connect pipes. They control flow. They change pipe directions. Both do similar jobs, but they’re made differently. They work in different ways too.

What Are Pipe Fittings?

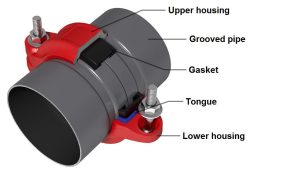

Pipe fittings are made by casting or cutting metal. They come in shapes like elbows, tees, reducers, and couplings. You see them in plumbing, gas lines, water systems, and big factory pipes. They’re made from stuff like PVC, stainless steel, carbon steel, or copper. Grooved pipe fittings are super popular! They’re fast and flexible for commercial or factory pipes. They don’t need welding or threading. That makes them great for quick projects.

What Are Forged Fittings?

Forged fittings are made by squishing metal under tons of pressure. This makes them super strong and dense. They’re used in tough spots like oil and gas pipes, chemical plants, or power stations. They come in threaded or socket weld types. They’re often carbon steel or stainless steel for extra toughness.

Where Are They Used?

Pipe fittings work great in low or medium-pressure systems. Think HVAC systems, fire sprinklers, or factory water lines. They’re perfect for modular or pre-built pipes. Forged fittings shine in hard-core places. Think oil refineries or offshore drilling rigs. They need to be super tough in extreme conditions.

How Are Pipe Fittings Different from Forged Fittings?

Knowing how they’re different helps you pick the right one for your job.

How They’re Made

Casting for Pipe Fittings

Pipe fittings are made by pouring hot metal into molds. This makes cool shapes. But it might leave tiny air bubbles or weak spots when the metal cools.

Forging for Forged Fittings

Forged fittings are made by squashing solid metal blocks. This lines up the metal’s grains. It makes them super strong. It cuts down on holes inside. They resist breaking or bending better.

Strength and Toughness

Forged fittings are denser. They’re way stronger than cast pipe fittings. They handle big stress without cracking. That’s why they’re great for tough jobs.

Handling Pressure and Heat

Forged fittings are champs at high pressure and heat. They stay leak-free in harsh spots. Grooved systems are for low or medium pressure. Forged ones can handle thousands of PSI, depending on the material. That’s super cool!

Which Is Better for Your Project?

Picking between pipe and forged fittings depends on your job’s needs.

Your Project’s Conditions

Got high pressure or hot pipes? Like steam lines or chemical plants? Go for forged fittings. For regular plumbing or HVAC with normal conditions, pipe fittings are just fine.

Cost and Savings

Pipe fittings cost less upfront. They’re easier to make. Grooved systems save on labor, but their parts might cost more than threaded ones. Forged fittings are pricier at first. But they last longer in tough spots, saving money over time.

Setup and Upkeep

Grooved joints don’t need hot work like welding. They’re fast to set up. They’re great for modular buildings where you need easy fixes. Forged fittings need skilled workers but are super sturdy.

Can You Mix Pipe and Forged Fittings?

You can mix them sometimes. But it’s tricky. You need to be careful.

Checking If They Work Together

Mixing fittings can cause problems. They might not fit perfectly. This could lead to leaks. Make sure materials match (like carbon steel with carbon steel). Check threads (NPT vs BSP) and pressure ratings too.

Risks of Mixing

Mixing wrong can cause leaks. Uneven stress or different metals might rust together. In big systems like gas or chemical pipes, this could be a huge mess.

Are There Rules for Quality?

Rules make sure fittings are safe and work well.

Rules for Pipe Fittings

Standards like ASME B16.9 (for butt-weld fittings), ASTM A234 (for carbon steel), and ISO 6182 (for grooved systems) keep quality steady. Design standards such as ISO6182, AWWA C606 guide makers to make good stuff worldwide.

Certifications for Forged Fittings

Look for ISO 9001 (quality control), PED (Pressure Equipment Directive), or API standards (for oil and gas). These show the fittings were tested toughly.

Why Choose Vicast for Your Fittings?

Want trusty fittings? Vicast is a super great choice!

About Vicast’s Products

Vicast has tons of products! Think grooved couplings, mechanical tees, crosses, elbows at angles like 11.25° or 22.5°, and grooved flanges rated up to 363 PSI. They’re perfect for HVAC, fire sprinklers, factory pipes, and tough jobs.

Focus on Quality

Started in 1982, Vicast has 40 years of know-how. They follow ISO 9001 rules super strictly. They helped make national standards. That’s a big deal! With over 200 patents, they’re always coming up with cool ideas.

Awesome Support and Global Reach

Vicast sells in over 100 countries. They deliver fast, no matter where you are. With 4,500 workers and 350 tech experts, they help from start to finish. From picking fittings to setting them up, they’ve got your back.

Why Pipe and Forged Fittings Are Awesome

These fittings make pipes work great! Pipe fittings are quick for school sprinklers or office HVAC. Forged fittings are tough for oil rigs or chemical plants. New grooved systems are super fast to install. Vicast’s gear makes projects a piece of cake!

FAQs About Pipe and Forged Fittings

Q1: What’s the big difference between pipe and forged fittings?

Pipe fittings are usually cast. Forged fittings are squished under pressure. This makes forged ones super strong for tough jobs.

Q2: Are forged fittings pricier than pipe fittings?

Yep! They cost more at first because they’re harder to make. But they last longer in rough spots, saving cash on fixes.

Q3: Can I use pipe fittings for hot systems?

Depends! Regular pipe fittings might not handle super high heat. Vicast’s grooved flange adapters work from -20°F to +180°F (-29°C to +82°C). Forged ones handle hotter temps better.