Torsional vibration is a major worry in machinery systems like pumps, compressors, and turbines. These machines form the core of many industrial activities. Such vibrations can act like hidden dangers. They cause wear and possible breakdown in shaft assemblies. Often, they show no clear warnings like loud noise or strong shaking. For plant operators, engineers, and maintenance teams, grasping and reducing torsion issues in couplings is vital. It ensures smooth operation, dependability, and safety. This blog looks at what causes torsional problems. It also covers useful plans to beat them. Plus, it explains how top-notch grooved pipe fittings, like those from Vicast, can help solve these difficulties.

Understanding Torsional Vibration in Machinery

Torsional vibration happens when machine parts like shafts and couplings twist. This twisting comes from different forces. These shakes can lead to big troubles. These include shaft wear, coupling breakdown, and shorter machine life. The results are often serious. Unplanned stops and expensive fixes hurt output.

What Causes Torsional Vibration?

Torsional vibrations start from many sources. These include electrical, mechanical, and aerodynamic forces. Here are main causes:

Electrical Forces:

In electrical machines like motors, air gap torque and sub-synchronous forces can become twisting actions. This happens especially when linked with current changes in the power grid.

Mechanical Forces:

Bad alignment, load shifts, and sudden events (like starts or stops) can cause torsional shakes.

Aerodynamic Forces:

Fluid forces on impellers, blades, or rotors in compressors and turbines add to torsional forces.

Low Damping:

Machinery systems often have weak torsional damping. This causes slow fading of shakes and strong torque peaks during resonances.

These reasons make torsional vibration a tricky problem. It needs careful study and action.

Why Torsional Issues Are Critical

Torsional problems can quietly harm machine parts. Couplings and shafts suffer from wear. Fatigue is nonlinear. This means even small twisting torques can cause major harm over time. Without proper watching and action, these issues can lead to:

- Sudden breakdowns in couplings or shafts.

- Rising upkeep costs from repeated fixes.

- Lowered operational effectiveness and reliability.

- Safety dangers for people and equipment.

Strategies to Overcome Torsion Issues

Fixing torsional vibration needs many methods. These include proper coupling choice, exact torsional modeling, and useful watching. Below, we describe key plans to lessen torsion issues in your couplings.

1. Select the Right Coupling Type

Couplings are very important for managing torsional action. Picking the right kind can greatly lower the chance of torsion problems. The two main kinds used in machinery systems are:

| Coupling Kind | Features | Common Uses | Benefits | Drawbacks |

| High-Torsional-Stiffness | Stiff, little flex, great dependability, handles misalignment | Pumps, compressors, turbines, electric motors | Great dependability, low upkeep, high natural frequency | Small flex for special cases |

| Flexible (Non-Metallic) | Low stiffness, strong damping, handles big misalignment | Special machines with special needs | Strong damping, fits certain cases | More upkeep, possible dependability problems |

High-Torsional-Stiffness Couplings:

These are often called metallic-flexible couplings. They are perfect for most vital machines. They keep high natural twisting frequencies away from the running speed range. This cuts the danger of resonance. Common types include disc-type and diaphragm-type couplings. These offer flex to deal with operational misalignment (like heat growth in turbines).

Flexible Couplings:

People use these in particular cases needing strong damping. Yet, their lower stiffness and greater upkeep needs make them less good for vital uses.

Suggestion:

For most industrial uses, high-torsional-stiffness couplings are better. They last long and need little care. Make sure the coupling is made to handle your machine’s exact working conditions. These include temperature shifts and thrust loads.

2. Conduct Accurate Torsional Modeling

An exact torsional model of the machinery system is essential. It helps check and lessen torsional vibration. Important points include:

Model Detail:

Use a good number of torsional parts based on know-how and rules. Focus on spots with big diameter changes or uneven shapes. These include shaft parts with seals and bearings.

Frequency Range:

Study the shake response across the operating speed range. This finds possible resonance spots.

Nonlinear Action:

Think about nonlinear twisting traits. This is especially true for non-metallic couplings where stiffness changes with torque load.

Good Method:

Do a sensitivity study to check damping results. Improve the model using real-world facts. This helps fix mistakes in torsional flex values, mainly for non-metallic couplings.

3. Enhance Torsional Damping

Boosting torsional damping can lower the size of shakes. It also lessens resonance dangers. Common damping ways include:

- Aerodynamic Damping:Fluid forces on impellers, blades, or rotors can give damping, especially in compressors and turbines.

- Material Hysteresis:Shaft stuff shows damping at high shaking strain levels.

- Coupling Damping:Non-metallic couplings offer greater damping through slipping or energy loss in flexible parts.

- Bearing Losses:Oil or magnetic bearings can add to damping, mainly in controlled systems.

Tip:

Aerodynamic and material damping are natural. But coupling choice can greatly change damping. Non-metallic flexible couplings give greater damping but need careful upkeep to avoid wearing out.

4. Implement Torsional Monitoring

Constant watching of torsional vibration is key for early finding of problems. Modern watching systems use new tools, like:

- Magnetic Pick-Up Probes:Measure torsional shaking through gear teeth or shaft encoders.

- Laser Optics:Give exact, no-touch measures of twisting action.

- Strain Gauges:Old-style but less common because they are hard to set up.

Why Watch?

Torsional watching gives live facts to check models, confirm coupling stiffness, and spot possible breakdowns (like cracks in coupling parts). Feedback from measures can improve study models and boost machine dependability.

5. Address Nonlinear Behavior and Degradation

Couplings, especially non-metallic ones, show nonlinear action as torque changes. This can move natural twisting frequencies. They might line up with force frequencies causing strong shakes or wear failure. To fix this:

- Do sensitivity studies to check nonlinear results and wearing out.

- Run torsional check tests during shop or site performance trials.

- Check couplings often for signs of damage. This is key for non-metallic parts that wear out easily.

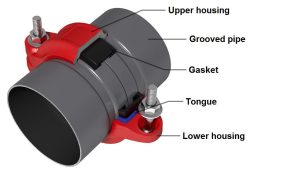

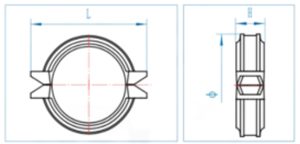

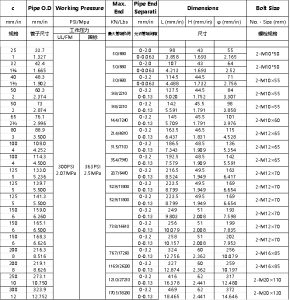

Vicast: Your Trusted Grooved Pipe Fitting Coupling Supplier

When beating torsion issues, high-quality couplings are key to success. Vicast is a top maker of grooved pipe fittings since 1982. They offer new and dependable answers for industrial uses. Their production site covers 1.4 million square meters. They have over 4500 workers. Vicast follows strict quality rules, including ISO 9001 and ISO 14001. Their grooved couplings, like the XGOT02 rigid grooved coupling, are built for toughness, exactness, and easy fitting. They are great for HVAC, fire safety, and other high-pressure setups. Vicast’s focus on new ideas and customer care ensures their items meet the tough needs of modern machinery systems. This helps you reduce torsional issues well.

Conclusion

Beating torsion issues in your couplings is a key move. It makes sure your machinery systems are dependable, effective, and safe. Choose the right coupling kind. Do exact torsional modeling. Boost damping. Set up watching systems. Deal with nonlinear action. Doing these can greatly lower the dangers linked with torsional vibration. Working with a trusted provider like Vicast gets you top grooved couplings. These meet the demands of your exact uses. With these plans in place, you protect your gear. You cut downtime. You make operational performance as good as possible.

FAQs

How do I know if my machinery is experiencing torsion issues?

Torsion issues might not cause clear signs like noise or visible shaking. Watch for indirect clues like sudden shaft or coupling wear, cracks in parts, or worse machine effectiveness. Using torsional watching systems can help find these issues early.

What is the best coupling type to overcome torsion issues?

High-torsional-stiffness couplings like disc-type or diaphragm-type are usually best for most machinery systems. They offer great dependability, low care, and keep natural twisting frequencies away from the running range. This reduces resonance dangers.

How can torsional monitoring help prevent coupling failure?

Torsional watching systems, like those using laser optics or magnetic probes, give live facts on shake levels. This lets you check torsional models, see shifts in natural frequencies, and spot possible breakdowns before they cause big harm.

Why is torsional damping important for overcoming torsion issues?

Torsional damping cuts the size of shakes. It stops strong torques during resonances. Ways like aerodynamic damping, material hysteresis, and non-metallic coupling parts can boost damping. But you must check them well for your exact use.

Can Vicast’s grooved couplings help address torsion issues?

Yes, Vicast’s grooved couplings, like the XGOT02, are made for toughness and exactness. They handle operational misalignment and high-pressure states. Their solid build helps keep steadiness and lower the danger of torsional vibration in machinery systems.