Grooved flanges are essential parts in current pipe networks. They provide a dependable, efficient, and adaptable approach for joining pipes in uses like heating and cooling systems, fire safety setups, and factory operations. Correct setup of these components guarantees sealed joints, improves network stability, and lowers upkeep expenses. This detailed manual guides you through putting in a grooved flange, sharing expert knowledge for lasting service and good operation. Whether you’re a pipe-fitting specialist or a construction supervisor handling a tube assembly, this reference helps reach excellent outcomes.

What is a Grooved Flange?

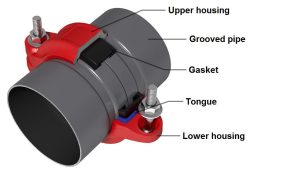

A grooved flange is a round piece made to link tubes or other line parts such as flow controllers and pressure adjusters. Different from older flange types, these parts use a ridged joining arrangement. This often removes welding or threading work. That makes them simpler to set up and service, especially in arrangements needing regular changes.

Key Features of Grooved Flanges

- Fastening Openings:Enable firm links with threaded rods, providing steadiness.

- Sealing Face:Offers a surface for packing material, creating a leak-free join.

- Ridged Shape:Permits rapid and solid fastening to prepared tube edges.

- Substance Standards:Usually produced from long-lasting substances for rust prevention and toughness.

These items work well in demanding settings, handling intense force and heat situations within set boundaries.

Why Choose Grooved Flanges?

These connection pieces bring multiple benefits compared to older welded or screwed types, becoming a top selection across fields.

| Feature | Benefit |

| Simple Setup | Needs no welding, cutting labor hours and expenses |

| Leak-Tight Joints | Packing elements ensure complete closing, avoiding drips and dangers |

| Adaptability | Permits easy adjustments and servicing, perfect for changing arrangements |

| Long Service Life | Top-grade substances endure difficult situations, promising extended use |

Uses cover heating and cooling arrangements, fire safety circuits, and factory piping where dependability and productivity are vital.

Step-by-Step Guide to Installing a Grooved Flange

Correct setup is vital for top operation of these connectors. Adhere to these stages for a firm and sealed link.

Pre-Installation Preparation

Before starting, take these actions for security and precision.

- Follow Personal Safety Gear Rules:Use eye shields, thick hand covers, head guards, and protective footwear. This guards against risks like sharp corners or heavy pieces. Employ breathing masks and ear defenders in dirty or noisy areas.

- Examine Supplies:Look over the flange, threaded rods, threaded caps, and packing ring for fractures, rust, or flaws. Confirm that all measurements match job needs using layout documents. Ensure the packing element has no rips or warping since it seals the connection.

- Clean Parts:Employ a metal brush or suitable cleaner to eliminate dirt, particles, or oil from the flange, packing ring, and tube ends. Scrub both flange sides and the tube’s prepared edge for smooth joining.

- Position Parts:Place the flange and tube on a solid platform. Use bubble gauges for correct positioning, modifying with metal supports if needed.

Installation Process

After preparation, follow these stages to set up the grooved flange.

Step 1: Place the Grooved Flange

Put the grooved flange onto the tube’s prepared edge. Make certain the groove lines up with the tube’s channel. Use two bubble gauges – one on the flange, one on the tube. Both should show level for ideal placement.

Step 2: Set the Packing Ring

Locate the packing ring between the flange and the tube or another flange. Ensure the ring’s middle matches the flange’s core. Confirm the ring entirely covers the sealing face to stop leaks. Finger-tighten threaded rods to hold the ring temporarily.

Step 3: Fasten the Joint

Place threaded rods through the flange’s openings and attach threaded caps. Tighten rods with a tension tool following maker instructions. Tighten rods in a crossing sequence for even force spread, preventing ring damage.

Step 4: Final Position Check

Recheck position using bubble gauges. Confirm the flange and tube stay level. Look at the packing ring for proper fitting and check for openings between parts.

Post-Installation Testing

To verify correct setup, do these checks:

- Perform a water pressure examination to spot leaks

- Use compressed air to test joint soundness

- Look closely for openings, misalignment, or noticeable harm

- If problems appear, take apart the joint, check parts, and repeat setup

Maintenance Tips for Grooved Flanges

For lasting operation and strength, follow these care methods:

- Yearly Checkups:Examine threaded rods for tightness and re-tension if required. Look at the packing ring for damage or distortion and change if necessary.

- Rust Observation:Watch for corrosion or color changes showing possible decay. Swap damaged pieces quickly to keep network soundness.

- Leak Finding:If drips appear, tighten rods or change the packing ring. Fix any unusual noises or movement right away to avoid joint breakdown.

Regular care lengthens your flange’s service period and ensures network security.

About Vicast: Your Trusted Grooved Flange Supplier

Founded in 1982, this maker leads in producing grooved connectors, including top-quality grooved flanges. Their huge production site employs thousands, combining modern facilities with strict quality checks. Their flanges meet worldwide benchmarks. Engineered for strength, accuracy, and simple setup, they suit heating and cooling, fire safety, and factory applications. Their dedication to new ideas and client support provides dependable answers for tube networks globally.

Conclusion

Setting up a grooved flange properly is key for achieving a solid, leak-tight, and long-lasting pipe connection. By following this detailed reference, you ensure expert installation meeting field norms and boosting network function. From preparation to testing, every stage matters for your job’s success. With high-quality parts and proper care, your tube arrangement will perform reliably long-term.

FAQs About Grooved Flange Installation

What equipment is required?

You’ll require a tension tool, bubble gauges, metal brush, threaded rods, threaded caps, and a packing ring. Safety items like hand covers and eye shields are also necessary.

How to guarantee leak-free links?

Ensure proper packing ring position, clean surfaces, and tighten rods evenly with a tension tool using a crossing pattern. Do water or air pressure checks afterward.

Can packing rings be reused?

Reusing rings isn’t suggested. They might be misshapen or harmed, causing drips. Always use fresh packing rings when redoing connections.

What are typical setup problems?

Usual difficulties involve wrong positioning, excessive rod tension, or employing flawed packing rings. These can be prevented by following correct alignment steps and checking supplies beforehand.