The Role of Grooved Flanges in Fire Protection Piping Systems: Codes and Best Practices

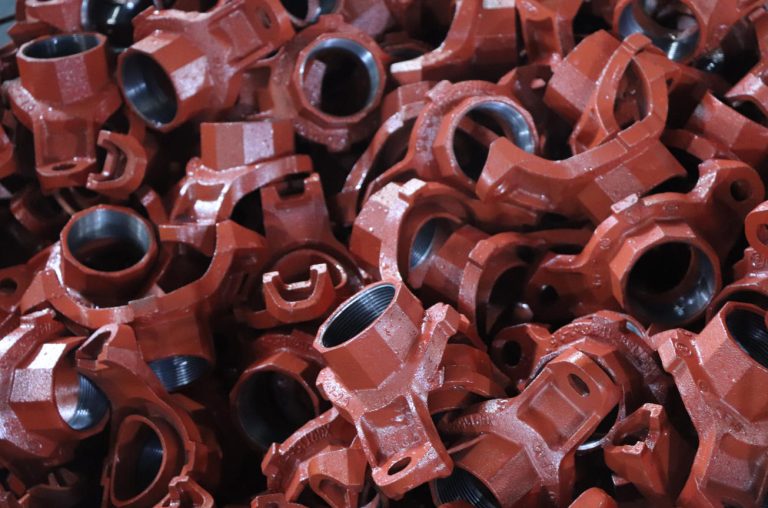

Fire protection piping systems act as quiet sentinels in buildings. They wait ready to act when time runs short. These setups carry water or foam to fight fires. Their dependability rests on parts like grooved flanges. These fittings join pipes firmly. They let fluids move under strain without breaking down. In critical spots—from tall offices to big storage areas—grooved flanges hold a main spot. They mix sturdiness with ease. This article looks closely at their job. It covers the rules that guide them. And it shares solid tips for using them well. Engineers and fitters will get real insights here. We break down how these pieces keep setups strong and up to code. Understanding Grooved Flanges Grooved flanges make a vital bond in pipe networks. Think of a plain pipe end. It looks smooth and straight. A grooved flange adds a cut groove around that end. This groove takes a