Want quick, leak-free pipe connections? Find out how grooved couplings make cam and groove systems super fast and super strong!

What Are Cam and Groove Couplings and Why Use Them?

Cam and groove couplings, also called camlock fittings, are quick-connect parts for fluid systems. They let you hook up hoses or pipes fast without tools. The system uses a male “adapter” that slides into a female “coupler.” Then, cam arms lock them tight.

Main Parts of Cam and Groove Couplings

The system has a few key pieces. There’s the male adapter that fits into the female coupler. Cam arms lock the connection. A gasket makes a tight seal. Safety pins or clips stop accidental unhooking. These parts come in materials like stainless steel, aluminum, brass, or polypropylene to fit different jobs.

Where They’re Used

Camlock fittings are super popular in lots of industries. You’ll find them in petroleum handling, chemical plants, food and drink factories, drug-making, farming, and firefighting. They’re great because you can connect and unhook hoses fast. This is perfect for jobs needing frequent changes or fixes.

Why Cam and Groove Systems Are Awesome

They’re super easy to use—no tools needed! They save time when setting up or taking down systems. Plus, they connect different hose types and sizes while keeping leaks low. Their tough build handles high-pressure jobs too.

How Does Grooved Coupling Work with Cam and Groove Systems?

Camlock fittings are great for quick hose connections. Grooved couplings help with pipe systems that need strong, flexible joints.

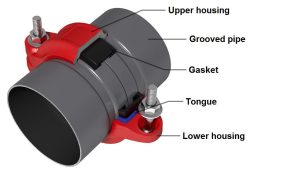

What Grooved Coupling Does for Pipes

Grooved couplings join two grooved-end pipes. They clamp around them with a gasketed housing. This is super useful in HVAC systems, fire protection setups, and factory pipelines. It keeps connections steady and controls vibration. Our rigid grooved coupling provides a robust and efficient solution for connecting pipes in a variety of applications, including HVAC, fire protection, and industrial systems.

How They Team Up with Camlock Fittings

Grooved couplings focus on pipe-to-pipe connections. Camlocks are for hose-to-hose or hose-to-pipe links. You can mix them using flange adapters or transition fittings. This combo lets you build systems that use both for flexibility.

Perks of Using Both Together

Pairing grooved couplings with camlock fittings makes systems super flexible. You can swap hoses fast while keeping pipes steady. This cuts downtime during fixes. It also keeps things leak-free under pressure, like in a fire sprinkler system.

Why Pick Grooved Coupling Over Old-School Methods?

Old ways like welding or threading take lots of time and money. They’re also harder to change. Grooved coupling has some big wins.

Faster Setup and Less Downtime

Grooved pipe systems don’t need welding or special workers. You just line up parts and clamp them. This makes setup super quick. It also cuts downtime for fixes, like in a busy factory.

Better Flexibility for System Design

Grooved couplings are easy to take apart. This makes rearranging or adding to pipe systems simple, like during a building upgrade. They also handle slight misalignments better than stiff joints.

Easier Upkeep

Grooved systems soak up vibrations better than rigid joints. This means less wear over time. Engineered for durability and ease of installation, this coupling ensures a leak-proof, secure fit that withstands high-pressure and temperature conditions.

Can Grooved Coupling Boost System Performance?

You bet! Grooved couplings don’t just make setup easier. They help your system work better in lots of ways.

Better Leak Protection and Strength

With its precision design and superior material quality, our rigid grooved coupling is the ideal choice for any project demanding strength, reliability, and long-lasting performance. Their gaskets press evenly around pipes. This stops leaks even when pressure changes, like in a water treatment plant.

Less Vibration and Noise

Grooved joints act like flexible hinges. They soak up shakes from pumps or fluid flow better than welded joints. This cuts noise in mechanical rooms or factories.

Safer for High-Pressure Jobs

Grooved couplings spread stress evenly. They avoid problems like weld cracks. This makes them super safe for high-pressure systems, like fire sprinklers or chemical lines.

Where Can You Get Trusty Grooved Pipe Fittings?

For solid solutions with proven quality, Vicast is a go-to name in grooved pipe tech.

Meet Vicast, a Top Supplier

Vicast offers tons of grooved pipe fittings for HVAC, fire protection, and factory pipelines. Their products are built to last and work great.

Vicast’s High-Quality Standards

Their fittings meet ASTM A536 Grade 65-45-12 and ASTM A395 Grade 65-45-15 standards. They follow design rules like ISO6182 and AWWA C606. This ensures they’re reliable in tough conditions.

Wide Range of Grooved Solutions

Vicast has everything from elbows (11.25°, 22.5°) to Mechanical Tees, Mechanical Crosses, and Flanges. Our Adaptor Flange provides a robust and efficient solution for connecting pipes in a variety of applications. They’re rated up to 363 PSI.

Awesome Support and Global Reach

Vicast’s products are in big projects like the Canton Tower and Guangzhou International Convention Center. They’ve got years of experience with major projects worldwide. Vicast offers great tech help and smooth delivery.

What Should You Think About When Picking a Grooved Coupling?

Choosing the right grooved coupling means looking at a few key things for your project.

Tips for Top Performance

Material Match

Make sure the coupling material fits your system’s environment. For example, pick cast iron or stainless steel based on rust risks, like in a coastal factory.

Pressure and Heat Limits

Check the operating limits. Vicast’s couplings handle temperatures from -20°F to +180°F (-29°C to +82°C). They also manage pressures up to 363 PSI, depending on the model.

Size Fit

Couplings need to match your pipe sizes, from DN25 to DN300. This ensures they work with your setup, like in a big office building.

How Do You Keep a Cam and Groove System with Grooved Couplings in Shape?

Regular care keeps your system running well. It stops costly leaks or breakdowns.

Check-Up Tips for Long Life

Look at gaskets often for wear. Check housing clamps for rust or damage. Make sure bolts stay tight per Vicast’s guidelines after system use.

Cleaning for Best Performance

Flush out dirt or gunk from hoses and pipes now and then. This is super important for sticky fluids, like in food factories. It keeps flow smooth across camlocks and grooved joints.

When to Swap Parts

Replace worn or cracked gaskets right away. If metal housings look bent from over-tightening or hits, swap them before they break under pressure.

Wrapping It Up

Mixing grooved couplings with cam and groove systems brings awesome benefits. They’re super fast to install, easy to maintain, and tough under pressure. This saves time and money in industries like HVAC or firefighting. Whether you’re upgrading a chemical plant or setting up sprinklers in a mall, Vicast’s products, like Grooved Pipe Fitting Coupling and Mechanical Tee, deliver trusty results. Choose Vicast for quality, safe, and budget-friendly solutions.

FAQs About Grooved Coupling in Cam and Groove Systems

Q1: Can grooved couplings handle high heat?

You bet! Most Vicast models work from -20°F to +180°F (-29°C to +82°C). They’re great for hot jobs like HVAC or factory lines.

Q2: Do grooved couplings need special tools?

Nope! You just need basic hand tools. This makes them faster and easier than welded or flanged options for setup and fixes.

Q3: Can grooved couplings be reused?

Totally! If they’re not damaged and gaskets are okay, you can reuse them during system changes. This saves cash compared to old methods.