Sick of slow, pricey pipe setups? Find out how grooved fittings can cut your project time in half and make things super reliable!

What Are Grooved Fittings and How Do They Work?

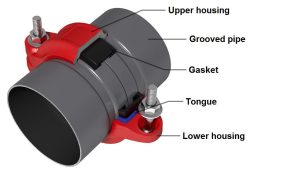

Grooved fittings are a super popular way to connect pipes without welding or threading. They use a special system that grabs onto grooves cut into pipe ends. A rubber gasket goes over the joint. Then, a metal housing clamps around it to make a tight, leak-free connection.

Main Parts of a Grooved Fitting System

A grooved fitting system has three big parts. First, there’s the grooved pipe ends. Next, a rubber gasket makes a snug seal. Finally, a metal coupling housing, held with bolts, keeps everything strong. This setup lets pipes move a bit for alignment or stretching. It’s awesome for systems like HVAC or fire protection.

How Grooved Fittings Are Different from Welded or Threaded Ones

Welded joints need heat and skilled workers. Threaded connections take a long time. They might leak later. But grooved fittings are super quick to install. They’re easy to fix too. They don’t need hot work permits. This cuts safety risks and speeds up projects.

Common Materials for Grooved Fittings

Most grooved fittings are made from ductile iron that meets ASTM A536 Grade 65-45-12 or ASTM A395 Grade 65-45-15 standards. This coupling ensures a leak-proof, secure fit that withstands high-pressure and temperature conditions. These materials are super strong. They fight rust. They last a long time.

Why Should You Think About Grooved Fittings?

Grooved fittings are awesome because they’re fast, save money, and work in tons of industries.

Benefits of Quick and Easy Setup

The best thing about grooved fittings is how fast you can put them in compared to old-school methods.

Lower Worker Costs

No welding or threading means you don’t need super skilled workers. This saves cash on labor. Plus, there are fewer safety rules to follow on-site.

Speedy Project Times

Grooved systems snap together with simple tools. This means quicker setups or fixes. It’s a huge win for projects with tight deadlines, like new office buildings.

Flexibility and Fix-Up Perks

Grooved fittings aren’t just fast. They make changes and repairs super easy.

Easy to Take Apart and Rearrange

You can remove grooved couplings without cutting pipes. This makes it simple to change things during renovations, like adding new pipes in a store.

Better for Repairs

If there’s a leak or clog, you can quickly take apart grooved sections to check or fix them. This cuts downtime. It keeps things running smoothly.

Where Are Grooved Fittings Used Most?

Thanks to their strength and flexibility, grooved fittings pop up in lots of places.

Common Uses in Big Buildings and Factories

Grooved piping systems are perfect for big projects where things need to stay solid.

HVAC Systems

Our elbow provides a tough and efficient way to join pipes in HVAC systems. Their flexibility handles heat changes while keeping seals tight.

Fire Protection Systems

Fire sprinklers love grooved fittings because they’re quick to install. They’re super safe too. This coupling ensures a leak-proof, secure fit that holds up under high-pressure and heat.

Plumbing and Water Systems

In city water lines or big buildings, grooved fittings make pipe setups faster. They stay reliable under different pressures, like in a hotel’s water system.

Good for Tough or Rusty Places

With its precision design and superior material quality, our rigid grooved coupling is the ideal choice for any project demanding strength, reliability, and long-lasting performance. They can handle pressures up to 363 psi. This makes them great for harsh spots like chemical plants or offshore rigs.

Can Grooved Fittings Save You Time and Cash?

You bet! They save time and money not just when you install them but for the whole life of your pipes.

How They Stack Up Against Old Pipe Methods

Welding takes more workers. It needs time for safety checks and cooling. Threaded pipes need extra effort too.

Material Costs vs. Worker Savings

Grooved parts might cost a bit more than threaded ones. But you save big on labor hours and tools. Overall, projects cost less, like when setting up pipes in a factory.

Long-Term Strength and Less Downtime

Grooved systems are built tough. They need fewer fixes over time. You can repair just one part instead of replacing whole lines. This saves time and money for years.

What Should You Look for in a Supplier?

Picking the right supplier means getting products that meet high standards. It also means support through your project.

Why Quality Rules Matter

Find makers who follow standards like ISO6182, AWWA C606, or GB 5135.11. These rules make sure products are the same every time you buy them.

Certifications and Testing to Check

Make sure products are tested for real-world stuff like pressure (up to 363 psi), temperature (-20°F to +180°F), and rust protection. These matter for your project’s needs, like pipes in a cold warehouse.

Who Is Vicast and Why Pick Them?

When you need trusty piping solutions in China, Vicast is a top name. They have years of know-how behind every product.

Vicast’s Products and Skills

Vicast has a huge range of stuff, like Grooved Pipe Fitting Coupling, Mechanical Tee, Mechanical Cross, and Flange. They’re made with ASTM-compliant ductile iron, Grade 65-45-12. They work in temperatures from -29°C to +82°C.

Focus on Quality, Trust, and Support

Vicast shows its commitment to excellence in every project. They were the designated brand for big projects like the 2008 Beijing Olympic venues. Choosing Vicast means choosing a symbol of quality and reliability. They back you up with great customer support too.

Wrapping It Up

Grooved pipe fittings are a super smart choice compared to old methods. They’re quick to install, easy to fix, and strong under pressure. Plus, they save money over time. Whether you’re upgrading a factory or setting up fire sprinklers in a mall, grooved fittings match your needs. Vicast’s wide range of certified products, like Grooved Pipe Fitting Coupling and Mechanical Tee, delivers trusty results every step. Pick Vicast for quality, safe, and budget-friendly piping solutions.

FAQs About Grooved Fittings

Q1: What pipe sizes work with grooved fittings?

Grooved fittings come in sizes from 1” (DN25) to 12” (DN300). They’re great for small home plumbing or big factory pipelines. Sizes range: 1 – 12″/DN25 – DN300.

Q2: Are grooved fittings leak-proof?

You bet! With good gaskets and housings, this coupling ensures a leak-proof connection. They hold up under high pressure, up to 363 psi. Working pressure: 363psi 2.5Mpa.

Q3: Can grooved fittings be reused?

Totally! You can take apart grooved couplings without hurting pipes or parts. This lets you reuse them during system changes or expansions. Easier disassembly allows reconfiguration.