Wanna know if super hot summer days can mess up your grooved pipe fittings? Let’s check out how heat affects how they work, which materials are toughest, and easy tricks to keep your pipes safe all summer long.

What Happens to Grooved Pipe Fittings in Crazy Heat?

In summer, grooved pipe fittings face high temps. This can change how well they work and how long they last. It depends on the stuff they’re made of, how well they’re put in, and how long they’re in the heat.

Heat Making Joints Stretch

When it gets hot, materials get bigger. This is called thermal expansion. In grooved pipe systems, this stretching can put extra pressure on joints. If the system isn’t built to move a bit, the pipes might not line up right. Over time, fittings could even come apart. This is a big deal for long pipes sitting in sunlight or near hot factory machines.

Gaskets and Seals Getting Soft

Rubber gaskets in grooved fittings can get hurt by heat. If they’re in high temps too long, they might get soft, lose their stretch, or change shape for good. This can make them leak or let pressure drop. Picking gaskets that can handle heat is super important in hot places or tough jobs.

How Heat Affects Fitting Strength

Going from hot to cold over and over can make metal parts weaker. This is called thermal fatigue. Grooved fittings are usually made from tough ductile iron, which handles temp changes pretty well. But if they’re always in super hot weather without care, they might wear out or rust faster.

Are Grooved Pipe Fittings Built for Summer Heat?

Grooved fittings are made with special materials and temp limits. This makes them good for lots of places, including hot summer days.

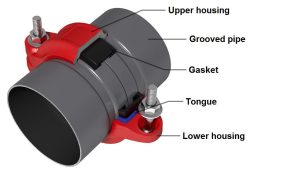

Materials in Grooved Fittings

Most grooved fittings use ductile iron that follows ASTM A536 Grade 65-45-12 or ASTM A395 Grade 65-45-15 rules. These materials are strong and stay steady in normal heat.

Temp Limits for Parts

Vicast products, like elbows, mechanical tees, couplings, and flanges, work from -20°F to +180°F (-29°C to +82°C). This covers most summer temps. But in super hot factories or deserts, they might hit their max limit.

Rules for Handling Heat

Good manufacturers make grooved fittings that follow rules like ISO6182, AWWA C606, and GB 5135.11. These rules make sure fittings work well in different conditions, including hot weather.

Can Long Sunlight Hurt How Fittings Work?

Summer isn’t just about hot air. Sunlight brings UV rays that can damage fittings over time, especially coatings and non-metal parts.

UV Rays and Coating Damage

UV rays can mess up paint or protective coatings on metal fittings. They might fade, get chalky, or peel off. If the coating breaks, the metal can rust when it gets wet or hits yucky stuff in the air.

Cracks or Color Changes Over Time

Rubber gaskets can get hurt by UV rays too. Without special UV-proof materials or covers, they might crack or change color after being in the sun a lot. This happens a lot in outdoor setups without shade.

Ways to Protect Outdoor Fittings

To keep fittings safe, use UV-proof coatings. Pick gaskets made for outdoor use. You can also wrap pipes with insulation or put them under a cover. This helps them last longer in hot seasons.

How Can You Keep Grooved Fittings Safe in Hot Weather?

Planning right and picking good materials are key to keeping your pipes working great in summer heat.

Picking the Best Materials for Hot Places

Rubber Gasket Choices

For hot areas, use EPDM gaskets rated up to 180°F (82°C). These stay stretchy in heat and fight off damage from UV rays or ozone.

Metal Choices

Ductile iron like ASTM A536 Grade 65-45-12 is tough and works well in hot or cold. It’s great for indoor factories or outdoor projects that face big temp changes.

Best Ways to Install in Summer

Lining Up and Tightening Right

Heat can make pipes shift a bit when you install them. Make sure everything lines up before tightening couplings. Use a torque wrench to tighten just right, following the maker’s rules.

Don’t Tighten Too Much in Heat

Tightening too much when it’s super hot can cause problems when pipes cool down at night. Try to install during cooler times, like morning or evening.

Why Check Fittings Often in Hot Seasons?

Checking fittings regularly helps you spot heat damage early. This stops small problems from turning into big, expensive ones.

Spotting Heat Damage Early

Look for signs like bulging gaskets, weird colors around joints, rust on metal from worn-out coatings, or loose couplings from heat changes. These mean you need to fix things quick.

Tips to Make Fittings Last in Hot Places

Put on anti-rust coatings every year if fittings are outside. Swap out old gaskets for new ones made for heat every few years, even if they’re not leaking yet. This keeps things safe.

Who Is Vicast and Why Pick Their Fittings?

When heatwaves hit, you need fittings you can trust. Vicast makes awesome products that stand out.

Vicast’s Focus on Quality

For over 40 years, Vicast has been big in China, covering all 34 provinces. They were picked for the 2008 Beijing Olympic venues. That shows how good they are.

Products and Rule-Following

Vicast has a bunch of products, like Grooved Pipe Fitting Coupling, Mechanical Tee, Mechanical Cross, Flange Adapter, and Elbows (11.25°–22.5°). They all follow rules like ISO6182 and AWWA C606, so they’re tough and safe.

Help and Reach Around the World

Vicast has offices in Tianjin and factories in Inner Mongolia and Hebei. They give great support with years of know-how. This helps your projects work, no matter the weather.

FAQs

Q1: Can grooved pipe fittings melt or bend in hot temps?

Nope! Fittings made from ductile iron like ASTM A536 Grade 65-45-12 handle up to 180°F (82°C). That’s more than most summer heat. But pick gaskets carefully for high temps.

Q2: Do I need special tools for installing in hot weather?

Regular tools work fine. Just use a torque wrench to tighten couplings right. Heat can make pipes expand, so follow Vicast’s tightening rules.

Q3: How often should I check grooved pipes in summer?

Check them once a month during hot months. Outdoor systems need extra looks to spot gasket wear or coating damage before leaks happen.